- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

In industrial scenarios with high temperature, high pressure or high frequency, traditional enameled wires are prone to problems such as insulation aging and decreased mechanical strength, resulting in increased equipment failure rates.

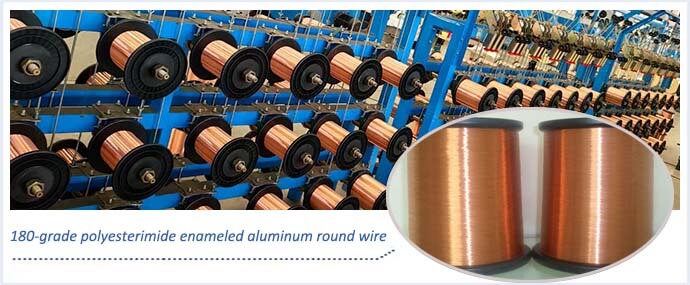

The 180-grade polyesterimide enameled aluminum round wire has become a “hard-core solution” for windings in high-temperature environments due to its unique materials and process design.

◆Thermal resistance advantage of polyesterimide resin

Polyesterimide is a high-performance engineering plastic with a molecular structure containing benzene rings and imide groups, which gives the paint film excellent heat resistance. The long-term working temperature can reach 180°C (H grade) and the short-term temperature shock resistance exceeds 200°C.

Compared with ordinary polyester enameled wire (temperature resistance 130°C), its temperature resistance level is increased by about 38%, significantly extending the service life of high-temperature equipment.

◆Double-layer composite coating process

Adopting a “polyamide + polyesterimide” double coating structure: the bottom layer of polyamide enhances adhesion and scratch resistance, and the outer layer of polyesterimide provides high temperature resistance and chemical corrosion resistance, and the two work together to improve the stability of the insulation layer.

The paint film thickness is uniform (in accordance with IEC 60317-25 standard), avoiding the risk of local breakdown at high temperatures.

◆Thermal management performance of aluminum conductors

The thermal conductivity of aluminum (237 W/m·K) is better than that of copper (401 W/m·K), but the aluminum wire density is lower (2.7g/cm³), and the heat dissipation efficiency per unit volume is higher, which is suitable for closed high-temperature environments that require rapid heat dissipation.

Thermal shock test: After circulating in a 220℃ high-temperature box for 1000 hours, the paint film remains intact and crack-free, and the adhesion rating is ≥ Level 2 (GB/T 4074.5 standard).

Thermal shock test: After circulating in a 220℃ high-temperature box for 1000 hours, the paint film remains intact and crack-free, and the adhesion rating is ≥ Level 2 (GB/T 4074.5 standard). Softening and breakdown resistance: softening and breakdown temperature ≥ 320℃, far exceeding the traditional polyurethane enameled wire (about 180℃), avoiding insulation failure when the motor is overloaded.

Softening and breakdown resistance: softening and breakdown temperature ≥ 320℃, far exceeding the traditional polyurethane enameled wire (about 180℃), avoiding insulation failure when the motor is overloaded. Chemical corrosion resistance: resistant to refrigerants (such as R134a), lubricating oil and acid-base environment, suitable for harsh scenarios such as air-conditioning compressors and industrial motors.

Chemical corrosion resistance: resistant to refrigerants (such as R134a), lubricating oil and acid-base environment, suitable for harsh scenarios such as air-conditioning compressors and industrial motors.

◆Industrial motors and power tools

Applicable to high-heating equipment such as injection molding machine motors and explosion-proof motors. The paint film maintains flexibility at high temperatures and reduces the risk of winding deformation. It can extend the life of the motor by 30%.

◆New energy vehicle drive system

High temperature resistance is suitable for electric vehicle motor windings (working temperature 150~180℃), and the lightweight characteristics of aluminum wire improve energy efficiency and help optimize the cruising range.

◆Power transformers and photovoltaic inverters

In dry-type transformers, the design of resistant to 180℃ temperature rise reduces the load of the cooling system and reduces operation and maintenance costs.

◆Core components of smart home appliances

In high-frequency and high-temperature scenarios such as microwave oven transformers and air fryer motors, the insulation performance of enameled wire is stable and has passed UL certification and ROHS environmental protection standards.

✅Technical customization: Supports customization of wire diameter Φ0.20mm~Φ5.00mm to meet the needs of special high-temperature equipment.

✅Global certification: Passed UL, IEC, GB and other certifications, adapted to the export high-end market.

✅Cost advantage: The price of aluminum wire is 20%~30% lower than that of copper wire, and the lightweight design reduces transportation and installation costs.

Consult our engineers now to get a special enameled wire solution for high-temperature scenarios! (The official website provides free sample application and technical parameter download, click to learn more→Click to Order )

Original Source:Magnet Wires for Power Industry