- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

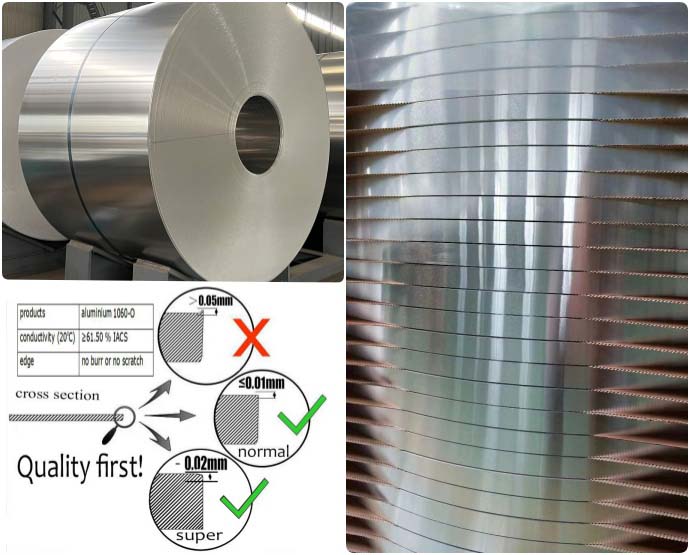

The alloys of aluminum strip for dry-type transformers are mainly 1060, 1050, 1070, etc., which are mainly used as conductive materials for high and low voltage windings of dry-type transformers. Transformer aluminum strips require certain tensile strength, elongation and conductivity. The conductivity of transformer aluminum strips produced by Flait Aluminum is 62%, the surface is smooth, and the edges are burr-free. The main alloys are: 1060/A1060, 1050/A1050, 1070/A1070, 1350; tempers: O/HO (soft status); thickness: 0.08-3.00mm.

1060 1050 1070 transformer aluminum strips start from the smelting and casting process of aluminum strips, and strictly control the process links such as smelting and casting, rolling, heat treatment, and finished product shearing. By controlling the alloy composition and optimizing the rolling and annealing process, the transformer aluminum strips achieve high conductivity and mechanical properties.

Alloys: 1060, 1050, 1070, 1350

Temper: O/HO

Thickness: 0.08mm-3.0mm

Width: 20mm-1600mm

Conductivity (% IACS): ≥ 61.5% IACS

Elongation (%): ≥20 (Thickness: 0.08-0.20); ≥25 (Thickness: 0.20-3.00)

Resistivity (Ω·mm² /m): ≤ 0.02825

Density in 20℃: 2.703kg/m3

ID: Ø 150mm, Ø300mm, Ø400mm, Ø500mm

Surface: Smooth, no scratches, the edges can be chamfered (rounded corners, rounded edges) without burrs.

Packing: wooden pallet, eye to sky/eye to wall.

| Thickness (mm) | Thickness tolerance range (mm) |

| >0.4~0.8 | ±0.03 |

| >0.8~1.1 | ±0.04 |

| >1.1~1.4 | ±0.05 |

| >1.4~2.0 | ±0.06 |

| >2.0~2.5 | ±0.07 |

| >2.5~3.0 | ±0.08 |

| Width (mm) | Width tolerance range (mm) |

| ≤341 | ±0.5 |

| >340~1000 | ±1.0 |

| Thickness (mm) | Burr height (≤) |

| 0.2~1.0 | 0.015 |

| 1.1~1.5 | 0.02 |

| ≥1.6 | 0.03 |

Original Source:https://www.flait-aluminum.com/Transformer-Aluminum-Strip.html

Tags:1050 Transformer Aluminum Strip,1060 Transformer Aluminum Strip,1070 Transformer Aluminum Strip