- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

Aluminum foil has good thermal and electronic conductivity and is widely used as the substrate (current collector) for cathode material coatings in lithium-ion battery research. Its naturally occurring oxide layer provides resistance to corrosion and oxidation at high electrical potentials. The thickness of aluminum foil is one of the key features of battery power density. The smaller the thickness, the greater the power density, but the cost will greatly increase. Currently, the industry generally believes that 0.012mm is the most popular thickness in battery research and development and industry.

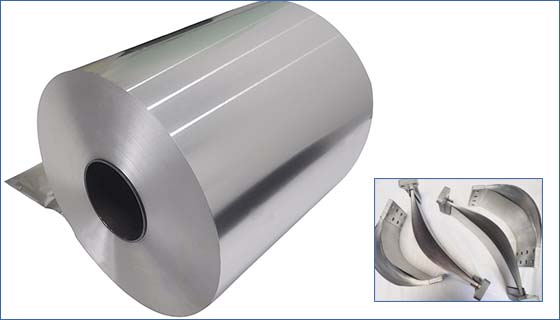

Flait Aluminum is the first in the industry to achieve mass production of 0.012mm ultra-thin, high-strength, high-elongation smooth power battery foil. Its main products are 1060 H18 aluminum foil and 1100 H18 aluminum foil. The products are supplied to many well-known power battery manufacturers at home and abroad, providing strong support for the lightweighting of power batteries, and have begun to gradually supply 0.010mm double-sided photovoltaic cell foil to the market.

1. Stable performance: Produced by hot-rolled billets, the processing rate is high, the grains are fully broken, the grains are fine, the finished battery foil has a uniform structure and stable mechanical properties.

1. Stable performance: Produced by hot-rolled billets, the processing rate is high, the grains are fully broken, the grains are fine, the finished battery foil has a uniform structure and stable mechanical properties. 2. Uniform thickness: Using advanced automatic thickness control system and automatic plate shape control system to achieve precise control of plate shape and thickness.

2. Uniform thickness: Using advanced automatic thickness control system and automatic plate shape control system to achieve precise control of plate shape and thickness. 3. High surface cleanliness: Using advanced online degreasing technology, the surface of the battery shell produced is bright and smooth, clean and free of oil stains.

3. High surface cleanliness: Using advanced online degreasing technology, the surface of the battery shell produced is bright and smooth, clean and free of oil stains.| Alloy | 1060 aluminum foil,1100 aluminum foil |

| Temper | H18 |

| Thickness(mm) | 0.009-0.02(Regular thickness:0.012) |

| Width(mm) | 200-1840 |

| Length(mm) | 4000-30000 |

| Category | Glossy aluminum foil |

| Surface | Single-sided glossy aluminum foil,double-sided glossy aluminum foil |

| Tensile strength | 190-280MPa |

| Elongation | ≥2% |

| Dyne value | ≥30 |

| Application | Power battery positive electrode substrate |

Original Source:https://www.flait-aluminum.com/Automobile-Aluminum-Sheet-Plate.html