- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

For more detailed information including pricing, customization and shipping.

The transformer is composed of four parts: winding, iron core, oil tank and insulating bushing. Its main parts are the winding and the core (body). The winding is the circuit of the transformer, and the core is the magnetic circuit of the transformer. The two constitute the core of the transformer - the electromagnetic part.

1060-HO/O transformer aluminum strip is made of high-quality pure aluminum, the aluminum content can reach more than 99.6%. 1060 aluminum strip and foil is the key raw material for manufacturing transformer windings, has unparalleled conductive properties from other series of aluminum strips and is one of the most commonly used alloys. Tempers are: O/HO. The thickness is between 0.08-3.00mm, and is also called: aluminum strip for dry-type transformers.

1060 aluminum strip foil has good elongation and tensile strength, and can fully meet conventional processing requirements (stamping, stretching) and high formability; it has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, heat treatment cannot strengthen and the machinability is not good; it can be gas welded, hydrogen atom welded and contact welded, but not easy to braze; it is easy to withstand various pressure processing and stretching and bending.

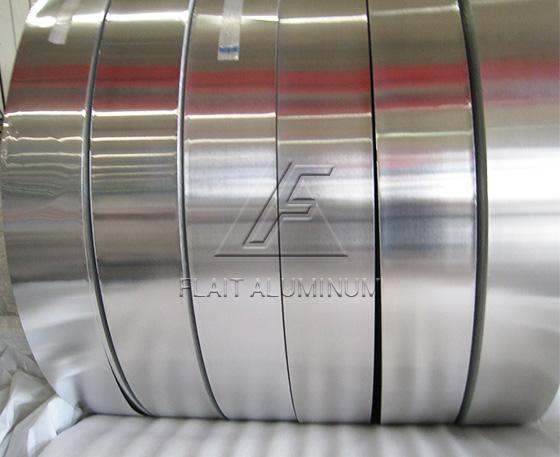

Flait Aluminum replys on the advantage technical and market advantages of the dry-type transformer raw material industry, starts from the aluminum strip casting process and strictly controls the casting, rolling, heat treatment, finished product shearing and other process. By controlling the alloy composition, optimizing the rolling and annealing process, enabling the product to achieve higher electrical conductivity and mechanical properties. Our company's transformer aluminum strips strictly control the quality of the base material and resolutely eliminate secondary materials, substitute materials, thereby stabilizing the performance of the transformer aluminum strips in the early stages of production and ensuring the stability of user use. In order to improve the precision and quality of transformer aluminum strips, we have updated the advanced slitting and slitting processing equipment to ensure that burrs, ruffles and other quality problems are eliminated during the production process of transformer aluminum strip products, and the edges can be 100% free burr.

| Alloy | 1060, 1060A |

| Temper | O/HO |

| Thickness (mm) | 0.08 - 3.00 |

| Width (mm) | 10 - 1500 |

| Conductivity (% IACS) | 1060-O ≥ 61.5% IACS |

| Elongation (%) | ≥20 (Thickness: 0.08-0.20) |

| ≥25 (Thickness: 0.20-3.00) | |

| U. T. S | 60-95N/mm2 |

| Density in 20℃ | 2.703kg/m3 |

| Resistivity (Ω·mm² /m) | ≤0.02825 |

| Burr's height | 0.01-0.03mm vary with thickness of the strip |

| Collapsed side's height | 0.05-0.1mm |

| ID | Ø 150mm,Ø300mm, Ø400mm, Ø500mm |

| Edge | Slit/Round |

| Surface | Smooth, free from scratches and impurities |

| Application | Transformer winding |

| Packing | Eye to wall and eye to sky, wooden pallet and wooden case |

| Sample | Available |

| Remark | Transformer aluminum strip can be customized |

Chemical composition of 1060 HO/O aluminum strip for transformers

| Alloy | Al (%) | Si (%) | Fe (%) | Cu (%) | Mn (%) | Zn (%) | Mg (%) | Ti (%) | V |

| 1060 | 99.6 | 0.0431 | 0.203 | 0.0022 | 0.0104 | 0.0093 | 0.0013 | 0.02 | 0.0039 |

Edge deburring range of 1060 HO/O aluminum strip for transformers

| Thickness (mm) | ≤0.20 | >0.20 |

| Burr | ≤0.03 | ≤0.05 |

| Camber | ≤0.5 | ≤2 |

| Layering | ≤4 | ≤5 |

Tolerance range of 1060 HO/O aluminum strip for transformers

| Alloys | 1060-O/HO | |||||||

| Thickness (mm) | 0.08-0.20 | 0.20-0.40 | 0.40-0.80 | 0.80-1.10 | 1.10-1.40 | 1.40-2.00 | 2.00-2.50 | 2.50-3.00 |

| Thickness Tolerance (mm) | ±8% of nominal thickness | ±0.02 | ±0.03 | ±0.04 | ±0.05 | ±0.06 | ±0.07 | ±0.08 |

| Width (mm) | <100 | 100-300 | 300-600 | 600-1250 | 1250-1500 | |||

| Width Tolerance (mm) | ±0.10 | ±0.20 | ±0.30 | ±1.00 | ±2.00 | |||

◆ High Electrical Conductivity

The 1060 aluminum strip foil exhibits excellent electrical conductivity, allowing efficient transmission of electrical currents within the transformer. This property helps reduce energy losses and enhances the overall performance of the transformer.

◆ Thermal Conductivity

Aluminum is known for its good thermal conductivity. The 1060 aluminum strip foil efficiently dissipates heat generated during transformer operation, preventing excessive temperature rise and ensuring the transformer's proper functioning.

◆ Lightweight

Aluminum is a lightweight material, making the 1060 aluminum strip foil an ideal choice for transformer windings. It helps reduce the overall weight of the transformer, making it more manageable during installation and transportation.

◆ Flexibility and Formability

The "O" temper of the 1060 aluminum strip foil provides excellent flexibility and formability. It can be easily bent, shaped, and wound into the desired configurations, facilitating the winding process during transformer manufacturing.

The 1060 aluminum strip foil is widely used in power transformers for low and medium voltage applications, distribution transformers, reactors and inductors, high-frequency transformers.