- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

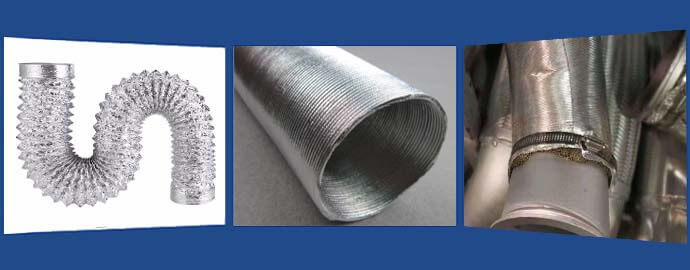

In the industrial era of pursuing high efficiency, energy saving and environmental protection, the selection of materials in the fields of automobiles, aviation, electronics, etc. has become particularly critical. 1060 aluminum alloy is gradually becoming the first choice of aluminum foil materials for exhaust pipes due to its unique performance advantages.

1. The core advantages of 1060 aluminum foil as exhaust pipes

1. The core advantages of 1060 aluminum foil as exhaust pipes◆ Excellent corrosion resistance and oxidation resistance

The exhaust pipe is exposed to high temperature, humidity and chemical corrosion environment for a long time, and the durability of the material is extremely high. The purity of 1060 aluminum foil is as high as 99.6%, and the naturally formed oxide film can effectively resist the erosion of corrosive media and significantly extend the service life.

◆ Lightweight design, reduce energy consumption

Compared with traditional steel, 1060 aluminum foil has low density and light weight, which can greatly reduce the overall weight of the exhaust pipe, thereby reducing vehicle energy consumption and improving power efficiency. It is especially suitable for the lightweight needs of new energy vehicles and aviation equipment.

◆ High thermal conductivity and heat dissipation performance

The exhaust pipe needs to dissipate heat quickly to avoid local overheating. The thermal conductivity of 1060 aluminum alloy is 237 W/(m·K), which can quickly distribute heat evenly and ensure stable operation of the system. It is particularly suitable for high-power engines and electronic cooling equipment.

◆ Excellent processing ductility

Whether it is stamping, stretching or welding, 1060 aluminum alloy can be easily formed to adapt to the design of exhaust pipes with complex structures. Its ductility reduces the difficulty and cost of processing, and is particularly suitable for customized production needs.

2. Application scenarios: comprehensive coverage from automobiles to high-end industries

2. Application scenarios: comprehensive coverage from automobiles to high-end industries◆Automobile manufacturing: 1060 aluminum foil is used for the inner wall coating or overall structure of the exhaust pipe to reduce the risk of rust, while improving fuel economy through lightweighting.

◆Aerospace: High temperature resistance and fatigue resistance make it an ideal choice for aircraft engine exhaust systems.

◆Electronic cooling: In the battery cooling module of new energy vehicles, the high thermal conductivity of 1060 aluminum foil can effectively manage heat loads and extend battery life.

3. User value: cost reduction, efficiency improvement and environmental protection win-win

3. User value: cost reduction, efficiency improvement and environmental protection win-win◆ Reduce maintenance costs

The corrosion resistance reduces the need for frequent replacement of parts, helping companies save long-term maintenance expenses.

◆ Improve product competitiveness

The combination of lightweight and efficient heat dissipation can help companies launch more energy-saving and better-performing products and seize market opportunities.

◆ Green and environmentally friendly

Aluminum can be 100% recycled, which is in line with the global carbon neutrality trend and enhances the brand’s sustainable development image.

The 1060 aluminum foil supplied by Flait Aluminum is precision rolled and surface treated, with customizable thickness (0.1mm-5mm), and supports coil or sheet supply to meet diverse needs. Cooperating customers can enjoy free technical consultation and fast delivery services to help you shorten the R&D cycle and accelerate market implementation. Contact us now to get samples and detailed parameter tables.Click to Order

Tags:1060 aluminum foil