- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

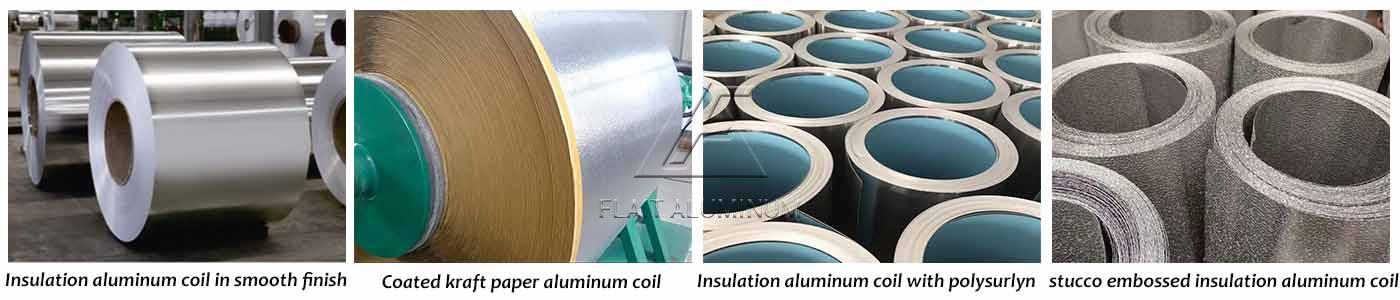

At present, the more commonly used products for pipe insulation aluminum coils are 1060 jacketing insulation aluminum coil and 3003 jacketing insulation aluminum coil. Our jacketing insulation aluminum coil is available in mill finish, smooth, stucco embossed, with moisture barrier consisting of polysurlyn and kraft paper. The pipeline insulation layer usually consists of three layers: insulation layer, protective layer, and waterproof layer. Indoor pipelines may not be provided with a waterproof layer. The main function of the insulation layer is to reduce heat loss, therefore, it must be composed of materials with low thermal conductivity. The outside of the insulation layer is usually made of asbestos fiber and cement mixture to make the asbestos cement shell protective layer, and its function is to protect the insulation layer. The outer surface of the protective layer is a waterproof layer to prevent moisture from entering the insulation layer. The waterproof layer/outer layer is often made of felt, jacketing aluminum coil or oiled glass cloth. Pipeline insulation aluminum coil is the waterproof layer/outer layer in pipeline insulation.

1060 Jacketing insulation aluminum rolls are mainly used for anti-rust and thermal insulation projects of pipelines, equipment, workshops, buildings and other facilities. Insulation aluminum coils are mainly divided into three types: 1 series pure aluminum, 3 series aluminum-manganese alloys, and 5 series aluminum-magnesium alloys. The 1 series pure aluminum is the most commonly used and the lowest price. 1060 Aluminum coil is the representative of the first-series aluminum coils, and has the highest cost performance. It is widely used in waterproofing of ordinary buildings and thermal insulation and rust prevention of municipal pipelines. However, 1060 pure aluminum coils are not resistant to acid and alkali corrosion, and are not suitable for heat preservation of equipment and pipelines in power plants and chemical plants.

3003 Jacketing insulation aluminum rolls belongs to Al-Mn alloy coil, also known as anti-rust aluminum coil. The aluminum content of 3003 thermal insulation aluminum coil is about 98%, and the manganese content can reach 1%. The hardness of 3003 jacketing insulation aluminum coil is high, because of the increase of manganese element, it is also very good in mechanical application. The strength, rust resistance, and corrosion resistance of 3003 aluminum coils are higher than 1060 aluminum coils, and the price is also higher than 1060 aluminum coils. 3003 Jacketing aluminum coils are often used for thermal insulation of refrigeration equipment, storage tanks, pressure vessels and pipes, heat sinks, etc.

| Alloy | 1050, 1060, 1100, 3003, 3105, 5005, 5052, etc. |

| Temper | H14, H16, H24, H26 |

| Thickness | 0.3-1.5mm |

| Width | 914mm, 1000mm, 1200mm, 1219mm, etc. |

| Length | 50′ (15 meters), 100′ (30 meters), 200′ (60 meters), 300′ (90 meters), Coil (specify lengths), Flat Sheets (cut to length), Cut & Rolled (to specific lengths) |

| Inner diameter | 75mm, 150mm, 305mm, 405mm, 505mm with or |

| without paper core | |

| Surface treatment | Mill finish, smooth/plain, stuccoembossed, corrugated |

| Moisture barrier | Polysurlyn, composite kraft paper |

| Surface lamination | Kraft paper laminated |

| Kraft paper thickness | About 0.1mm |

| Polysurlyn thickness | About 0.076mm (3mil) |

| Quality standard | ASTM B209,ISO9001, GB/T3880 |

| Quantity | Have ready stock for most common thickness roll small quantity order are acceptable. |

The aluminum coil is corrosion-resistant and does not rust. Insulation aluminum coils are mostly used in humid environments, such as pipe insulation in power plants and chemical plants. Other insulation materials are not as corrosion-resistant as aluminum coils, and their lifespan is short, repeated construction is required every few years; aluminum coils will not rust and have a long service life, can effectively save costs.

The aluminum coil is corrosion-resistant and does not rust. Insulation aluminum coils are mostly used in humid environments, such as pipe insulation in power plants and chemical plants. Other insulation materials are not as corrosion-resistant as aluminum coils, and their lifespan is short, repeated construction is required every few years; aluminum coils will not rust and have a long service life, can effectively save costs. The appearance of the thermal insulation aluminum coil is beautiful. Compared with other insulation materials, the silver-white metallic luster of aluminum coils is recommended to be prominent and can be maintained for a long time.

The appearance of the thermal insulation aluminum coil is beautiful. Compared with other insulation materials, the silver-white metallic luster of aluminum coils is recommended to be prominent and can be maintained for a long time. Aluminum coils are more valuable, and waste aluminum can be recycled. Compared with other insulation materials, the recycling price of scrap aluminum can reach more than 80% of the price of aluminum ingots. Through scrap aluminum recycling, manufacturers can recover most of the invested funds, which makes insulation aluminum coils a cost-effective insulation material.

Aluminum coils are more valuable, and waste aluminum can be recycled. Compared with other insulation materials, the recycling price of scrap aluminum can reach more than 80% of the price of aluminum ingots. Through scrap aluminum recycling, manufacturers can recover most of the invested funds, which makes insulation aluminum coils a cost-effective insulation material.

Original Source: https://www.flait-aluminum.com/Aluminum-Jacketing-Coil-Roll.html