- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

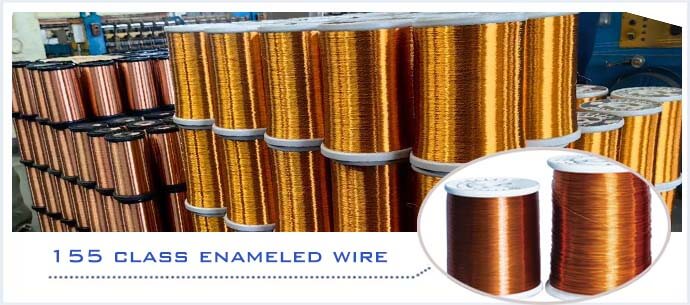

In high-temperature scenarios such as industrial motors, new energy drive systems, and frequency conversion equipment, traditional enameled wires often age and declass due to excessive temperature rise, and even cause downtime risks. How to choose an enameled wire that can withstand high-temperature shocks and ensure long-term stable operation of the equipment? 155 class enameled wire has become an ideal solution for high-temperature environments with its excellent temperature resistance and reliability.

◆ Insulation failure risk: 130 class (B class) enameled wire is prone to paint cracking under continuous high temperatures (>130°C), resulting in short circuits or equipment burnout.

◆ Energy efficiency loss: Excessive temperature rise will increase resistance, cause energy waste, and affect equipment output power.

◆ Maintenance cost increases: Frequent downtime to replace coils and repair faults directly pushes up corporate production costs.

✅Solution: Upclass to 155 class enameled wire (H class insulation), and the temperature resistance level is increased to 155°C, breaking through the limitations of high-temperature environments on equipment performance!

1. Excellent high temperature resistance and doubled insulation stability

1. Excellent high temperature resistance and doubled insulation stability✔ Material upclass: Polyesterimide + polyamideimide composite coating is used. The paint film is flexible and not brittle at high temperature. It can withstand high temperature of 155℃ for a long time (up to 180℃ for a short time) to avoid the risk of insulation failure.

✔ Comparative advantage: Compared with 130 class enameled wire, the temperature resistance is improved by 20%, and the life span is extended by more than 2 times.

2. Energy saving and high efficiency, reducing the cost of the whole life cycle

2. Energy saving and high efficiency, reducing the cost of the whole life cycle✔ Better conductivity: 99.99% high-purity copper core, 15% reduction in resistance loss, and improved equipment energy efficiency.

✔ Flexible design: Supports more compact coil design, reduces material usage, and reduces space occupation cost.

3. Adapt to harsh scenarios and widely used

3. Adapt to harsh scenarios and widely used✔ Industrial field: high temperature and high load equipment such as welding machines, variable frequency motors, and high-voltage transformers.

✔ New energy field: electric vehicle drive motors, charging piles, and photovoltaic inverter cooling systems.

✔Smart devices: 5G base station power supply, drone motors and other miniaturized, high-performance scenarios.

◆ Product: 155 class High Temperature Enameled wire

◆ Wire core material: copper, aluminum

◆ Temperature resistance level: 155℃ (H class)

◆ Breakdown voltage: ≥8000V (conventional model)

◆ Wire diameter range: 0.1mm-5.0mm (customization supported)

◆ International standard certification: IEC 60317, UL certification, compliant with RoHS environmental protection directive.

Whether you are an industrial equipment manufacturer, a new energy enterprise, or an integrator who needs high-performance wires, 155 class enameled wire can provide long-term and stable core guarantees for your products!

✅Contact us:

Free sample application: Experience the temperature resistance and conductivity of 155 class enameled wires;

Technical consulting support: A team of professional engineers provides you with selection and design optimization suggestions.

Original Source:Magnet Wires for Power Industry