- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

For more detailed information including pricing, customization and shipping.

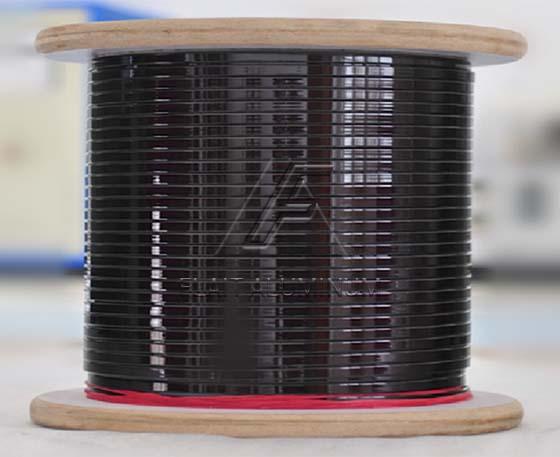

200/220 class polyamide-imide enameled aluminum (copper) flat wire is a special enameled wire resistant to ultra-high temperatures. It is made by drawing metals such as copper or aluminum into the required round wire, then drawing or extruding it into a flat shape through a die, and evenly coating the surface with polyamide-imide paint, and then baking and other processes.

Polyamide-imide paint, referred to as PAI, is a high-performance insulating paint and one of the paints with the highest temperature resistance at present. 200/220 class refers to the temperature resistance grade of the enameled wire, indicating that the maximum temperature it can withstand during long-term work is 200℃ and 220℃ respectively, corresponding to Class C in the international standard.

| Product type | QXYLB-200 | QXYLB-220 | QXYB-200 | QXYB-220 |

| Material | Aluminum | copper | ||

| Size | a:2mm-5mm b:3.5mm-16mm | a:1.18mm-5mm b:2.8mm-16mm | ||

| Paint film thickness | 1 grade (thin film), 2 grade (standard film), 3 grade (thick film) | |||

| Insulating paint type | Polyamide-imide(XY) | |||

| Temperature resistance level | C Grade | |||

| Standard | IEC-60317、GB/T、JIS、NEMA、RoHS | |||

◆ Larger surface area: Compared with round wires of the same cross-sectional area, flat wires have a larger surface area, which is conducive to heat dissipation, reducing coil temperature rise and improving the efficiency of electrical equipment.

◆ Higher filling factor: In the same winding space, flat wires can be wound with more turns, improving the inductance and performance of the coil, and reducing the volume and weight of the equipment.

◆ Excellent heat resistance: It can work for a long time in a high temperature environment of 200℃ or even 220℃, and is one of the enameled wires with the highest temperature resistance.

◆ Excellent electrical properties: It has excellent insulation and excellent voltage breakdown resistance.

◆ Excellent mechanical strength: It has good tensile, bending and wear resistance, which is convenient for winding coils.

◆ Excellent chemical corrosion resistance: It can resist the erosion of a variety of chemical substances, including acids, alkalis, solvents, etc.

It should be noted that polyamide-imide paint has higher heat resistance, but is also more expensive; it is easy to hydrolyze in a water-containing sealing system; it is incompatible with chlorine-containing polymer compounds such as polyvinyl chloride and chloroprene rubber, and is incompatible with salts containing chloride ions; the aluminum core enameled wire has poor conductivity and is not suitable for electrical windings of high-power, short-term overload, and long-term motors. When selecting and using it, it is necessary to choose according to specific needs.

Due to its extremely excellent high temperature resistance, 200/220 class polyamide-imide enameled aluminum rectangular wire is widely used in motors, electrical appliances, instruments and other products that require extremely high heat resistance and reliability.

Special motors: such as aerospace motors, military motors, high-temperature industrial motors, deep well pump motors and other motors that need to work in extreme environments.

Special motors: such as aerospace motors, military motors, high-temperature industrial motors, deep well pump motors and other motors that need to work in extreme environments. High temperature transformers: Special transformers used for power transmission and voltage conversion, especially transformers working in high temperature and high frequency environments.

High temperature transformers: Special transformers used for power transmission and voltage conversion, especially transformers working in high temperature and high frequency environments. Special electromagnetic coils: Coils used in various special electromagnetic equipment, such as high temperature sensors, high temperature actuators, etc.

Special electromagnetic coils: Coils used in various special electromagnetic equipment, such as high temperature sensors, high temperature actuators, etc.