- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

For more detailed information including pricing, customization and shipping.

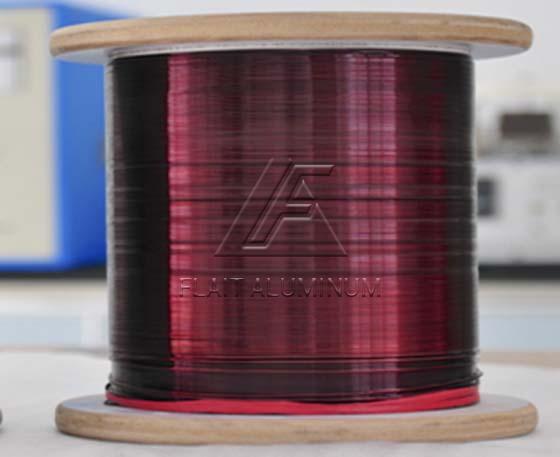

200/220 class polyamide-imide enameled aluminum round wire is an ultra-high temperature resistant enameled wire, belonging to high-performance special enameled wire. The product is made of electrical round aluminum rods that are annealed by die drawing of the required specifications, and then painted with polyamide-imide paint on the surface and then processed by baking and other processes.

Polyamide-imide paint is a high-performance insulating paint with extremely excellent heat resistance, electrical properties, mechanical properties and chemical corrosion resistance. It is one of the paints with the highest temperature resistance level at present. 200/220 class refers to the temperature resistance level of enameled wire, indicating that the maximum temperature it can withstand during long-term work is 200℃ and 220℃ respectively, corresponding to Class C in the international standard.

| Product type | QXYL-200 | QXYL-220 |

| Material | Aluminum | |

| Diameter | 0.30mm-6.00mm | |

| Paint film thickness | 1 grade (thin film), 2 grade (standard film), 3 grade (thick film) | |

| Insulating paint type | Polyamide-imide(XY) | |

| Temperature resistance level | C Grade | |

| Standard | IEC-60317、GB/T、JIS、NEMA、RoHS | |

◆ Excellent heat resistance: It can work for a long time in a high temperature environment of 200℃ or even 220℃, and is one of the enameled wires with the highest temperature resistance at present.

◆ Excellent electrical properties: It has excellent insulation and excellent voltage breakdown resistance.

◆ Excellent mechanical strength: It has good tensile, bending and wear resistance, which is convenient for winding coils.

◆ Excellent chemical corrosion resistance: It can resist the erosion of various chemical substances, including acids, alkalis, solvents, etc.

◆ Excellent moisture resistance: It is not easily affected by humid environments.

◆ Good radiation resistance: It can also maintain good performance in some special environments.

It should be noted that polyamide-imide paint has higher heat resistance, but the price is also more expensive; it is easy to hydrolyze in a water-containing sealing system; it is incompatible with chlorine-containing polymer compounds such as polyvinyl chloride and chloroprene rubber, and is incompatible with salts containing chloride ions; due to the special shape of flat wire, its winding process is more complicated than round wire, and special winding equipment and processes are required, and the tension during the winding process is strictly controlled to ensure the quality of the coil.

200/220 class polyamide-imide enameled aluminum (copper) flat wire is widely used in motors, electrical appliances, instruments and other products with extremely high requirements for heat resistance, heat dissipation and filling factor due to its extremely excellent high temperature resistance and unique advantages of flat wire.

Special motors: such as aerospace motors, military motors, high-temperature industrial motors, traction motors, special frequency conversion motors and other motors that need to work in extreme environments.

Special motors: such as aerospace motors, military motors, high-temperature industrial motors, traction motors, special frequency conversion motors and other motors that need to work in extreme environments. High temperature transformers: Special transformers used for power transmission and voltage conversion, especially transformers working in high temperature and high frequency environments, such as dry transformers, special transformers, etc.

High temperature transformers: Special transformers used for power transmission and voltage conversion, especially transformers working in high temperature and high frequency environments, such as dry transformers, special transformers, etc. Special electromagnetic coils: Coils used in various special electromagnetic equipment, such as high temperature sensors, high temperature actuators, solenoid valves, etc.

Special electromagnetic coils: Coils used in various special electromagnetic equipment, such as high temperature sensors, high temperature actuators, solenoid valves, etc. New energy vehicle drive motors: Flat wire windings have significant advantages in improving motor power density and efficiency, so they are increasingly used in high power density new energy vehicle drive motors.

New energy vehicle drive motors: Flat wire windings have significant advantages in improving motor power density and efficiency, so they are increasingly used in high power density new energy vehicle drive motors.