- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

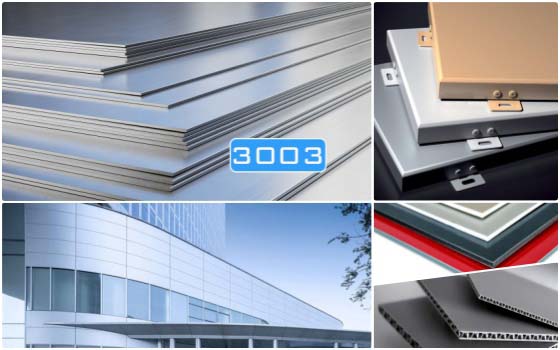

Aluminum alloy panels are often used in the selection of modern curtain wall panels. Thanks to the material properties and high cost performance of aluminum alloys, people are more willing to use it to replace traditional stone curtain walls and glass curtain walls. Commonly used curtain wall panels include 1060 aluminum sheet and 1100 aluminum sheet of 1 series aluminum alloy, 3003 aluminum sheet of 3 series aluminum alloy, 5005 aluminum sheet and 5052 aluminum sheet of 5 series aluminum alloy. Different alloys are available depending on the application and budget. Today I bring you an introduction to 3003 curtain wall aluminum panels.

As the most commonly used rust-proof aluminum, 3003 aluminum sheet is one of the most commonly used materials for outdoor curtain walls. It has higher strength and surface smoothness than 1 series aluminum alloy, and the price is much lower than 5 series aluminum alloy. Although it is not as suitable as 5052 aluminum sheet for marine environment applications, its corrosion resistance is fully capable for general outdoor curtain wall applications.

| Alloy | Temper | Thickness(mm) | Width(mm) | Length(mm) |

| 3003 | H14,H24 | 1.5-4.0 | 20-2000 | 500-16000 |

| Application | Curtain wall aluminum panels, aluminum veneers, aluminum-plastic panels, aluminum honeycomb panels, etc. | |||

3003 aluminum sheets are commonly used in curtain walls in two states, namely 3003 H14 and 3003 H24. H represents the cold work hardening state, and the following numbers represent the different degrees and types of cold work hardening. H1 represents the pure work hardening state, which is the last cold-rolled product without additional heat treatment. The product has relatively high hardness and strength and tensile strength. Low intensity. H2 indicates work hardening and incomplete annealing state. The last step of the product is heat treatment. As a result, the processed product has low hardness and high tensile strength. 3003 H14 represents the product’s tensile strength greater than 140MPa, and 3003 H24 represents the product’s strength greater than 240MPa.

| Alloy–Temper | Thickness (mm) |

Tensile Strength Rm/Mpa |

Yield strength Rp0.2/Mpa |

Elongation % |

Bending radius | |

| 90° | 180° | |||||

| 3003 H14 | 0.2-6.0 | 145-195 | ≥125 | 2-4 | 0.5t-2.0t | 2.0t |

| 3003 H24 | 0.2-6.0 | 145-195 | ≥115 | 4-6 | 0.5t-2.0t | 1.5t |

As a professional aluminum sheet manufacturer, Flait Aluminum provides 3003 aluminum sheets for curtain walls in various states and sizes. Conventional thicknesses include 1.5mm, 2.0mm, 2.5mm, 3.0mm and 4.0mm. They are lightweight, corrosion-resistant and easy to process. , environmental protection and other characteristics. The products can be used to make various curtain wall aluminum panels, aluminum veneers, aluminum-plastic panels, aluminum honeycomb panels, etc.

Tags:3003 aluminum sheet,1060 aluminum sheet,1100 aluminum sheet,5005 aluminum sheet,5052 aluminum sheet