- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

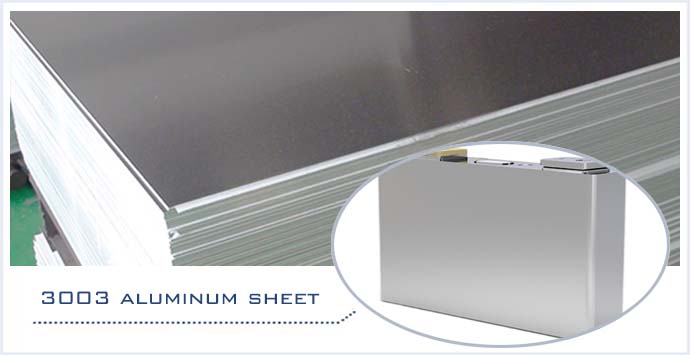

3003 aluminum sheet is a widely used aluminum-manganese alloy known for its excellent formability and moderate strength. In the annealed state (O state), 3003 aluminum sheet exhibits extremely high plasticity, which allows it to be effectively deformed during stretching without being easily cracked. The combination of high ductility and strength makes 3003 aluminum sheet an ideal choice for applications that require complex forming and deep drawing, such as power battery housings.

3003 O aluminum is 3003 aluminum in the annealed state, and it has the highest ductility compared to other variants of 3003 aluminum. 3003 aluminum sheets in this state are highly formable, meaning they can be easily stretched and shaped into complex and delicate designs. This property is critical in the manufacture of power battery housings, which often require precise sizes and shapes to fit specific equipment and vehicles.

| Alloy | 3003 aluminum sheet |

| Temper | O,H14 |

| Thickness(mm) | 0.8-3.0 |

| Width(mm) | C |

| Length(mm) | C |

| Standard | ASTM B209/EN 485/GB/T 33227-2016/JIS H4000 |

| Alloy-Temper | 3003 O | 3003 H14 |

| Tensile Strength Rm(Mpa) | 110 | 160 |

| Yield Strength Rp0.2(Mpa) | 40 | 130 |

| Elongation at Break | 28% | 8.30% |

| Brinell Hardness | 28 | 42 |

Excellent formability: good plasticity, high ductility, good deep drawing forming ability.

Excellent formability: good plasticity, high ductility, good deep drawing forming ability.  Lightweight design: light weight, conducive to product structure optimization.

Lightweight design: light weight, conducive to product structure optimization.  Corrosion resistance: reduce the risk of leakage caused by corrosion.

Corrosion resistance: reduce the risk of leakage caused by corrosion.  Processability: good cold processing, improve strength and impact resistance.

Processability: good cold processing, improve strength and impact resistance.

Original Source:Automobile Aluminum Sheet Plate

Tags:3003 aluminum sheet