- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

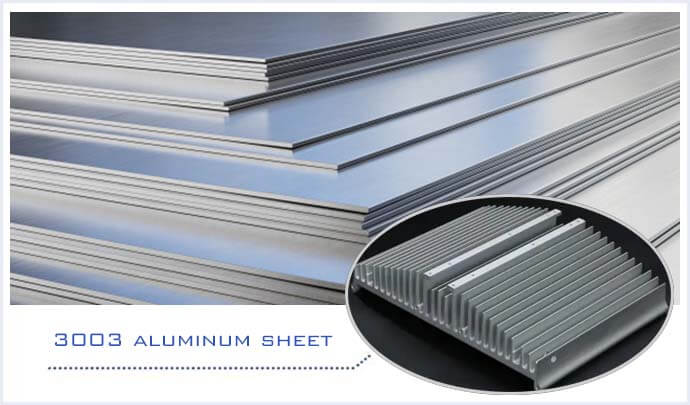

Radiators are key components widely used in many fields, which ensure the normal operation of equipment and systems. 3003 aluminum sheet/coil is mainly composed of aluminum, manganese and a small amount of silicon alloy material. Aluminum itself is a light and soft metal with good electrical and thermal conductivity, while the addition of manganese and silicon enhances the mechanical properties and corrosion resistance of aluminum.

The superior mechanical properties, corrosion resistance and heat dissipation performance of 3003 aluminum coil give it a unique advantage in the production of radiator accessories. The good ductility of 3003 aluminum coil allows aluminum coil to be easily processed into various shapes and sizes to meet the diverse needs of radiator stamping accessories.

After the surface of 3003 aluminum alloy is treated, the oxide film formed on its surface has good corrosion resistance, which can effectively resist the erosion of the atmosphere, water and some chemicals, ensuring that the radiator accessories can maintain their performance and appearance for a long time during use.

3003 aluminum sheet and coil is a general aluminum alloy material with good strength and corrosion resistance, and has demonstrated its wide applicability in many fields. It is commonly used to manufacture automobile body panels, fuel tanks, coolers, air conditioners, heat exchangers and radiators. 3003 aluminum sheet has good forming properties and can be used for processing and forming of various complex shapes. Compared with other aluminum alloy materials, 3003 aluminum sheet has higher ductility and strength, which can meet the requirements of material strength and corrosion resistance in different fields.

As a professional aluminum processing company, Flait Aluminum can produce aluminum materials required for radiators. The company has strong production strength and advanced technical equipment, and can produce aluminum sheets and strips of various specifications and models, including aluminum sheets and aluminum foils for radiators. It can customize 3003 cast aluminum coils, 3003 hot-rolled aluminum coils, and 3003 ultra-wide aluminum coils according to customer needs.

With high strength and hardness

With high strength and hardness3003 aluminum sheets and coils can withstand the pressure and stress generated by the radiator at work, ensuring the stability and durability of the radiator. In addition, the aluminum sheet also has good toughness, which helps to absorb part of the impact energy when it is impacted or squeezed, reducing the risk of accidents caused by brittle fracture.

Excellent thermal conductivity

Excellent thermal conductivity3003 aluminum coil can quickly transfer heat from the inside of the radiator to the outside, improving the heat dissipation efficiency. At the same time, it has good corrosion resistance and can be used for a long time in a variety of environments without being easily damaged.

Easy to process and produce

Easy to process and produce3003 aluminum alloy is easy to cut, stamp, bend and other processing operations, and can easily manufacture shapes and sizes that meet the design requirements of the radiator.