- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

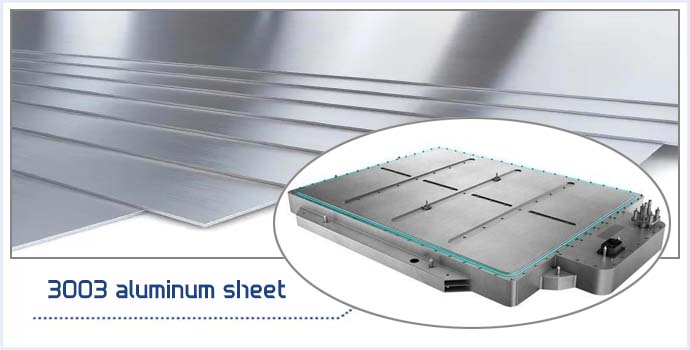

Since the development of the automobile industry, lightweight and environmental protection have increasingly become the pursuit of the automobile manufacturing industry, and new energy vehicles have become the choice of more and more families. In new energy vehicles, a large number of lithium battery packs are needed. Since each module is composed of several battery boxes, the more battery boxes there are, the heavier the weight. In order to reduce weight and increase the driving range, lightweight materials must be used. Today we are discussing the most commonly used battery shell material-3003 aluminum sheet.

As one of the representative alloys of aluminum alloys, 3003 aluminum alloy is mainly composed of aluminum, manganese, copper and other elements, and the manganese content is usually between 1.0-1.5%. The chemical composition of this alloy gives it excellent corrosion resistance, especially in the atmosphere, fresh water and sea water environments, which is close to the corrosion resistance of industrial pure aluminum.

Alloy: 3003

Temper: O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H112, etc.

Thickness: 0.2-500mm

Width: 20-2650mm

Length: 500-16000mm

Standard:ASTM B209/EN 485/GB/T 33227-2016/JIS H4000

Application:Energy power battery shell,water cooling plate, etc.

1. Good forming and processing characteristics, high corrosion resistance, good weldability and heat dissipation;

1. Good forming and processing characteristics, high corrosion resistance, good weldability and heat dissipation; 2. Impact resistance, not easy to crack and leak, can meet the strength and rigidity requirements of power battery shell;

2. Impact resistance, not easy to crack and leak, can meet the strength and rigidity requirements of power battery shell; 3. 3003 aluminum sheet has low density and light weight, which can reduce the weight of the whole vehicle and improve the vehicle’s endurance;

3. 3003 aluminum sheet has low density and light weight, which can reduce the weight of the whole vehicle and improve the vehicle’s endurance; 4. 3003 power battery shell material is one of FLAIT ALUMINUM’s advantageous products, with mature technology, excellent quality and global delivery.

4. 3003 power battery shell material is one of FLAIT ALUMINUM’s advantageous products, with mature technology, excellent quality and global delivery.

3003 aluminum sheet has good formability, good plasticity and high pressure resistance. The power battery shell made of 3003 aluminum sheet is impact-resistant, not easy to break and leak, and can meet the requirements of the power battery shell for strength and rigidity. Moreover, aluminum alloy has low density and light weight, which can reduce battery weight, increase battery capacity density, make the battery work stably, indirectly reduce the weight of the vehicle, and increase vehicle endurance.

3003 aluminum sheet has become an ideal material for power battery shell due to its light weight, high strength, corrosion resistance and good processing performance. With the increasing demand for electric vehicles and other high-performance batteries, the application prospects of 3003 aluminum alloy will be broader.

Original Source:https://www.flait-aluminum.com/Automobile-Aluminum-Sheet-Plate.html

Tags:3003 aluminum sheet