- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

For more detailed information including pricing, customization and shipping.

3104 Aluminum coil has good deep drawing performance, proper elongation, good corrosion resistance and processing performance, and can be smelted and processed into alloys with different hardness according to different application requirements. 3104 Aluminum coils are often used to make power battery casings in lightweight vehicles, cooking utensils, food storage devices, tanks and warehouses on transportation equipment, sheet metal pressure vessels and pipes, etc.

|

Alloy |

3104 aluminum coil strip |

|

Temper |

F,O,H12,H14,H16,H18,H19,H22,H24, |

|

Thickness(mm) |

0.2-10 |

|

Width(mm) |

100-2650 |

|

Length(mm) |

C |

|

ID |

Ø505mm or customized |

|

Package |

Eye to sky or Eye to wall |

|

Application |

Canning materials, oxidation materials, beer filling, cola filling, lamp head materials, shutters, LCD backplanes, cake trays, aluminum substrates for color coating, etc. |

Chemical composition:

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Zn |

Cr |

Others |

Al |

|

|

3104 |

0.60 |

0.70 |

0.05-0.20 |

1.00-1.50 |

- |

0.10 |

- |

Single |

Total |

Remain |

|

0.05 |

0.15 |

|||||||||

Mechanical properties:

|

Alloy & Temper |

Tensile strength Rm/Mpa |

Yield strength Rp0.2/Mpa |

Elongation % |

Earring |

|

3104-H19 |

290-320 |

265-290 |

≥4 |

≤2.5 |

3104 Aluminum coil has good deep drawing performance, elongation, corrosion resistance and processing performance.

3104 Aluminum coil has good deep drawing performance, elongation, corrosion resistance and processing performance. 3104 Aluminum coil has good elongation and excellent corrosion resistance.

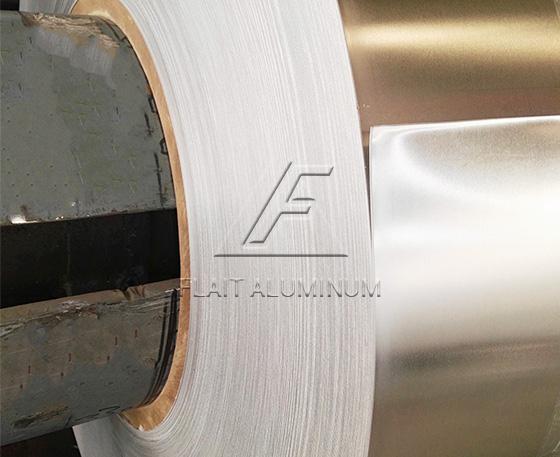

3104 Aluminum coil has good elongation and excellent corrosion resistance. The surface quality of 3104 aluminum coil is good, no oil spots, waves, scratches, roll marks, neat trimming, no burrs.

The surface quality of 3104 aluminum coil is good, no oil spots, waves, scratches, roll marks, neat trimming, no burrs.3104 Aluminum coil is used in lamp head materials, shutters, can materials, oxide materials, aluminum substrates for color coating, cake trays, bottle cap materials, LCD backplanes, etc.e appliances, etc. The fields that do not require high product strength.

3104-H19 Aluminum coil for beverage can bodies: has high strength and formability, the coil can be formed into the cylindrical shape of the tank and maintaining its structural integrity.

3104-H16 Aluminum coil for auto parts: car panels, covers or other parts.

3104-H14 Aluminum coil for cookware: has deep draw capability, makes it suitable for making cookware such as pots, pans and bakeware. The coil can be formed into complex shapes while maintaining structural integrity.

3104-H14 Aluminum coil for heat exchanger fins: The ductility of the H14 temper favors the formation of heat exchanger fins, which require specific shapes to improve heat transfer efficiency.

3104-O Aluminum coil for cable wrapping: annealed 3104 aluminum coils are available for applications requiring high formability, such as wrapping cables and wires. This soft material can be easily molded into irregular shapes.