- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

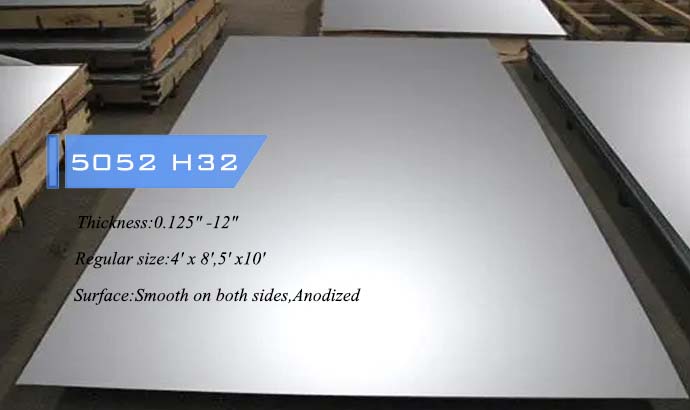

Under the dual trends of industrial upgrading and green transformation, the optimization of material performance has become a core element for companies to enhance their competitiveness. As a benchmark product in the field of aluminum-magnesium alloys, 5052 H32 aluminum plate has become the preferred material in the fields of high-end manufacturing, construction engineering and new energy with its scientific ratio, precision process and adaptability to multiple scenarios.

Innovation in material science

Innovation in material scienceAdopting Al-Mg alloy system, the magnesium content is precisely controlled at 2.2%~2.8%, supplemented by trace elements such as chromium and manganese to optimize the grain boundary structure, achieving a scientific balance between strength and ductility.

The tensile strength of 5052 H32 aluminum plate is 230~305 MPa, and the yield strength is ≥190 MPa (ASTM B209 standard), which is significantly better than conventional 5 series aluminum plate and meets the mechanical requirements of heavy-loaded structural parts.

Long-term protection system

Long-term protection systemThe natural oxide film and work hardening work together to pass the 4800-hour neutral salt spray test (ISO 9227), and the corrosion resistance reaches the marine engineering grade standard, which is suitable for extreme environments such as coastal and chemical industries.

Precision processing compatibility

Precision processing compatibilityThe H32 heat treatment state (1/4 hard state) ensures that the plate has both formability and dimensional stability, supports complex processes such as stamping, bending (minimum bending radius ≤2T), welding (TIG/MIG qualified rate ≥99%), and greatly reduces the processing loss rate.

| Application Industry | Typical Applications | Performance effect |

| High-end transportation equipment | New energy vehicle battery trays, high-speed rail carriage structural parts, ship decks | Reduce weight by 15%~30%, improve battery life, and reduce life cycle costs by 40% |

| Green Building | Super high-rise curtain wall, photovoltaic support, low-carbon energy-saving roof system | 50-year weather resistance guarantee, reducing maintenance frequency and helping LEED certification |

| Precision Industrial Manufacturing | Semiconductor equipment frames, medical instrument housings, aerospace non-load-bearing components | Zero pollution, anti-electromagnetic interference, in line with ISO 13485/AS9100 standards |

| New energy infrastructure | Energy storage containers, wind turbine blade connectors, hydrogen storage tank liners | Low temperature resistance (-50℃) and anti-fatigue properties ensure safety in extreme working conditions |

◆ Raw material traceability: The raw materials of 5052 H32 aluminum plates are all from the world’s top aluminum suppliers such as Aluminum Corporation of China and Alcoa, ensuring an aluminum purity of more than 99.7%, and each batch comes with a material certificate (MTC).

◆ Intelligent manufacturing process: Introduce the German SMS hot rolling production line and Japanese UBE CNC quenching equipment, thickness tolerance control ±0.02mm, plate flatness ≤5I unit.

◆ Testing and certification: Passed CNAS laboratory certification, provides full-size mechanical property reports, metallographic maps and third-party SGS test documents, in line with ASTM, EN, JIS and other national standards.

◆ Sustainable commitment: The carbon footprint traceability system of the production process has passed ISO 14064 certification, and 100% of recyclable materials account for helping customers achieve ESG goals.

◆ Agile delivery: 5,000 tons of standing inventory, support 72-hour emergency order response, and global mainstream ports arrival cycle ≤30 days.

◆ Deep customization: Provide full-specification products with thickness of 0.2mm-600mm and width of 200mm-2500mm, support customized treatments such as surface anodizing (AA15-AA25) and fluorocarbon spraying (PVDF).

◆ Technical empowerment: 24-hour online engineering team, providing value-added services such as FEA simulation analysis and processing technology optimization, to help products seamlessly connect from design to mass production.

Original Source:Aluminum Sheet for Tank Truck / Fuel Tanker