- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

5083-H116 corrosion-resistant aluminum plate belongs to the aluminum-magnesium alloy aluminum plate and hot-rolled aluminum plate series. The main alloy element is magnesium, and the magnesium content is between 3-5%. The weight of aluminum-magnesium alloy is lower than other alloy series in the same specification. 5083-H116 Aluminum plate produced by Flait Aluminum adopts continuous casting and rolling processing technology. It has low density, high tensile strength, high elongation, good forming performance, corrosion resistance, weldability, and oxidation deep processing performance. 5083-H116 corrosion-resistant aluminum plates are commonly used in the transportation field, such as automobile fuel tanks, aircraft fuel tanks, automobile doors, seals, etc.; they can also be used in shipbuilding and tank truck industries.

5083-H116 aluminum plate and 5083-H321 aluminum plate:

5083-H116 temper: aluminum alloy with a magnesium content of not less than 3.0%, after anti-corrosion treatment; has good corrosion resistance.

5083-H321 temper: used for processing materials with magnesium content greater than 4%; has good corrosion resistance and more stable performance.

5083-H116 and 5083-H321 aluminum plates have better corrosion resistance and are more suitable for the marine underwater environment than H111 and H112 tempers. Although the temperatures of 5083-H116 and H321 aluminum plates are slightly different during the production process, their corrosion resistance is significantly better than other tempers. 5083-H116 aluminum plate and 5083-H321 aluminum plate have mechanical properties and spalling corrosion resistance requirements. The mechanical properties of 5083-H116 aluminum plate and 5083-H321 aluminum plate are similar, and they both have good anti-corrosion properties after painting.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Al |

| 5083 | 0.40 | 0.40 | 0.10 | 0.40-1.00 | 4.00-4.90 | 0.05-0.25 | – | 0.25 | 0.15 | – | Remainder |

| Alloy | Temper | Tensile strength Rm(Mpa) | Yield strength Rp0.2(MPa) | Elongation A(%) | Hardness HBWα | Certification |

| 5083 | O/H111/H112 | ≥275 | ≥125 | ≥16 | – | DNV, GL, ABS, CCS, BV, LR |

| H116 | ≥305 | ≥215 | ≥10 | 89 | ||

| H321 | 305-295 | 215-295 | ≥12 | – |

| Alloy & Temper | Thermal expansion coefficient (20-100℃) µm/m•k | Melting point range (℃) | Conductivity 20℃ (68°F) (%IACS) | Resistivity 20 (68°F) Ωmm2/m | Density (20℃) (g/cm³) |

| 5083-H116 | 24.2 | 574-638 | 29 | 0.0595 | 2.75 |

| Alloy | Temper | Thickness (mm) | Width (mm) | Length (mm) |

| 5083 | O,H12,H14,H16,H18,H19,H22,H24, H26,H28,H32,H34,H36,H38,H111, H112,H114,H116,H321,etc. |

3.00-50.00 | 2000 or customized | 6000/8000/9000/12000 or customized |

| Surface treatment | Rolled, patterned aluminum plate | |||

| Package | Export packaging (protective film, interleaved paper) | |||

| Sample | Available | |||

Composition and properties: strengthen the selection and quality control of raw materials, implement relevant standards and specifications, strictly inspect and test the compositions and properties of 5083 aluminum sheets.

Composition and properties: strengthen the selection and quality control of raw materials, implement relevant standards and specifications, strictly inspect and test the compositions and properties of 5083 aluminum sheets. Specifications: using advanced processing technology and equipment, strengthen size control and adjustment during production process according to your actual needs, including thickness, width, length and other parameters.

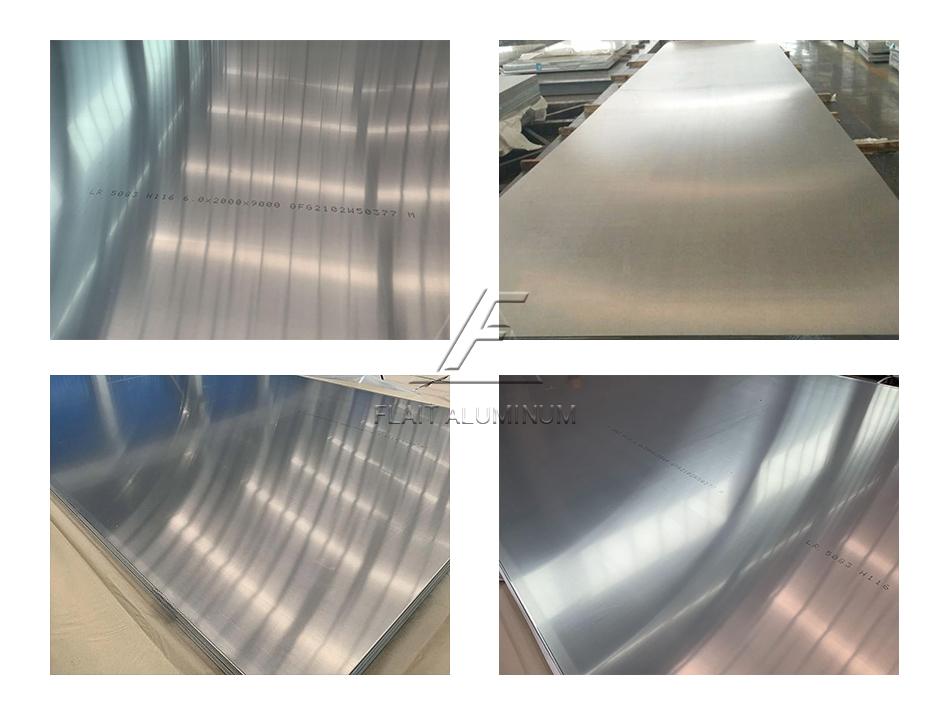

Specifications: using advanced processing technology and equipment, strengthen size control and adjustment during production process according to your actual needs, including thickness, width, length and other parameters. Surface quality: the surface of 5083 aluminum plate is smooth and flat, without obvious protrusions and depressions, and no cracks, oxidation, flaws and other obvious defects.

Surface quality: the surface of 5083 aluminum plate is smooth and flat, without obvious protrusions and depressions, and no cracks, oxidation, flaws and other obvious defects. Services: Flait Aluminum has a special quality inspection team, which takes pictures of customers before each shipment and provide inspection reports.

Services: Flait Aluminum has a special quality inspection team, which takes pictures of customers before each shipment and provide inspection reports. Package and transportation: standard export package, short production lead times, sufficient aluminum sheets in stock.

Package and transportation: standard export package, short production lead times, sufficient aluminum sheets in stock.

Tag: 5083 aluminum plate