- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

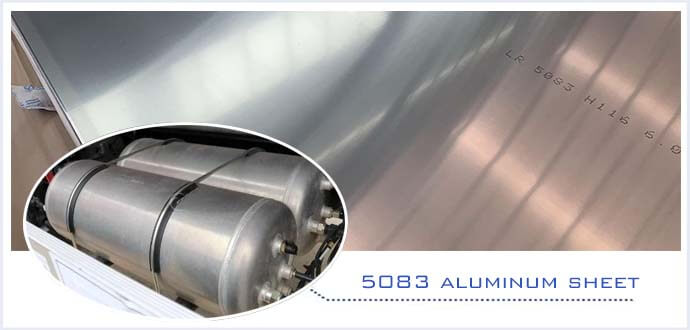

The air tank is a gas storage device in the automobile braking system, mainly used for automobile braking, honking, etc., and is commonly found in large vehicles such as trucks. For safety and lightweight considerations, the material of the air tank has changed in recent years. Aluminum air tanks have gradually replaced iron air tanks and become the mainstream.

Aluminum air tanks generally use 5083 aluminum sheet or 5052 aluminum sheet. The main alloy element is magnesium. It has good corrosion resistance, excellent weldability, good cold workability, and medium strength. It is in line with the current trend of lightweight trucks and has obvious advantages in manufacturing air tanks.

◆ Alloy: 5083

◆ Temper: O, H14, H16, H18, H116

◆ Thickness: 0-6mm

◆ Width: 800-1600mm

◆ Length: C

◆ Tensile strength: 275-350MPa

◆ Elongation after fracture: ≥13%

1. Lightweight, with outstanding lightweight advantages, it helps to improve fuel efficiency and reduce emissions.

1. Lightweight, with outstanding lightweight advantages, it helps to improve fuel efficiency and reduce emissions. 2. Corrosion resistance, a dense oxide film is naturally formed on the surface to protect the gas tank from corrosion.

2. Corrosion resistance, a dense oxide film is naturally formed on the surface to protect the gas tank from corrosion. 3. Very good processing performance, excellent weldability, and high elongation.

3. Very good processing performance, excellent weldability, and high elongation. 4. The material can be recycled, energy-saving and environmentally friendly.

4. The material can be recycled, energy-saving and environmentally friendly.

5083 O Aluminum sheet

5083 O Aluminum sheetThe O state indicates that the aluminum alloy has been fully annealed, with maximum ductility and minimum strength. In this state, the aluminum sheet has a low tensile strength but excellent formability. It is suitable for the manufacture of gas tanks that require complex shapes and can withstand certain pressures, but is not suitable for extreme loads.

5083 Hxx Aluminum sheet

5083 Hxx Aluminum sheet◎5083 H14 Aluminum sheet: Moderate work hardening, providing higher strength and durability.

◎5083 H16/H18 Aluminum sheet: Highly work hardened, with stronger tensile strength and yield strength.

Aluminum sheets in these states are very suitable for gas tanks because they can withstand higher pressures and impacts while maintaining good weldability and corrosion resistance, ensuring that the gas tanks operate safely under high pressure environments, and are very suitable for gas tank applications in heavy vehicles.

Original Source:Automobile Aluminum Sheet Plate

Tags:5083 aluminum sheet