- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

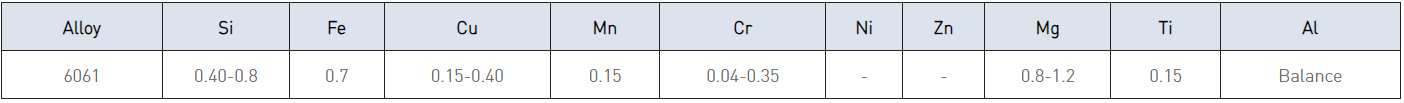

6061 aluminum sheet plate belongs to the 6 series aluminum-magnesium-silicon alloy, has high strength, good corrosion resistance, weldability, and oxidation effect. However, due to its complex processing technology and high technical requirements, the price is higher than ordinary aluminum plates. Commonly used tempers of 6061 aluminum sheets plates include O, T4, T6, T651, etc. The T651 temper is formed by stretching on the basis of the T6 temper to eliminate internal stress, making it more suitable for processing and forming; different tempers have different application fields; 6061 aluminum plate is mainly used for automated mechanical parts, precision machining, automobile chassis, molds, etc.

| Alloy | 6061-T6 Aluminum sheet plate | 6061-T651 Aluminum sheet plate |

| Temper | After 6061 aluminum alloy undergoes solution heat treatment, artificial aging is performed. During solution treatment, aluminum alloys are heated to high temperatures and then rapidly cooled to increase hardness. Next, it is heated again to a lower temperature and aged to further enhance the material’s properties. 6061-T6 aluminum sheet has good strength and corrosion resistance. | The 6061 aluminum alloy is stretched and balanced based on the T6 state. This process is called Stretching Balance Treatment. Its purpose is to make the internal stress distribution of the aluminum alloy more uniform by adjusting it. Therefore, 6061-T651 aluminum sheet has better mechanical properties and resistance to deformation. |

| Use | 6061-T6 aluminum plate is used for various industrial structural parts that require high strength, weldability and corrosion resistance, such as manufacturing trucks/cars, construction, ships, furniture, mechanical parts, precision machining, molds, etc. | 6061-T651 aluminum plate is generally used in products with higher requirements, such as electronic and precision instruments, medical equipment, automated machinery parts, precision machining, mold manufacturing, etc. |

6061 aluminum alloys with the same composition, 6061-T651 has higher mechanical properties, deformation resistance and better stability than 6061-T6. The T6 temper is suitable for processing, but may cause processing deformation due to large internal stress; the T651 temper is more suitable for precision processing and products with higher requirements, such as precision instruments and medical equipment, by eliminating internal stress.

Normally, if there are no requirements for dimensional stability and elasticity, the 6061-T6 aluminum plate is selected; if is a precision workpiece, in order to avoid elastic recovery after processing that causes inaccurate dimensions, the 6061-T651 aluminum plate is selected. Select the appropriate heat treatment state according to the needs of the specific application. Please contact us for a free quote and samples.

Tags:6061 aluminum sheet