- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

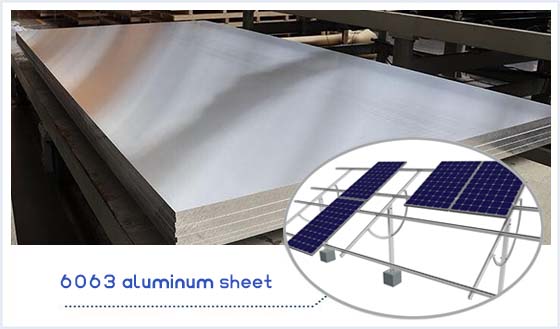

Solar panel bracket is a special bracket designed for placing, installing and fixing solar panels in solar photovoltaic power generation system. The general materials are aluminum alloy and stainless steel. Aluminum alloy solar panel bracket has a market share that has surpassed steel brackets due to its beautiful, light and durable characteristics. 6063 aluminum plate is the most commonly used material for photovoltaic brackets.

Aluminum alloy solar panel brackets mainly uses 6063 aluminum plate. 6063 aluminum plate has good processability, good corrosion resistance, high toughness and good oxidation effect. It is used in various industrial structural parts that require certain strength, weldability and high corrosion resistance.It is an ideal material for distributed photovoltaic brackets on building roofs with load-bearing requirements.

Good processability

Good processability6063 aluminum plate can be easily processed into the required specifications of aluminum profiles through sawing, drilling, punching, folding and other processes, and the energy consumption of the processing process is much lower than that of steel.

Good corrosion resistance, can be anodized

Good corrosion resistance, can be anodized6063 aluminum plate has good resistance to natural corrosion and galvanic corrosion, and has excellent anodizing effect. The aluminum alloy photovoltaic brackets made of it can adapt to the outdoor environment for a long time, and the product life can reach more than several decades.

High strength and high plasticity

High strength and high plasticity6063 aluminum plate belongs to Al-Mg-Si series high plasticity alloy, with good strength, good earthquake resistance, wind resistance, snow pressure resistance, corrosion resistance and other physical properties.

Light weight and recyclable

Light weight and recyclable6063 aluminum plate is only 1/3 of the weight of steel. Its products are lightweight and practical, and are very convenient for transportation and installation. At the same time, aluminum is a recyclable metal, which meets the requirements of economy and recyclability.

Alloy: 6063

Temperature: T5, T6

Product type: aluminum profile, aluminum plate, aluminum strip, etc.

Thickness: 0.30-500mm

Width: 500-2650mm

Surface treatment: smooth surface, anodizing, powder coating, PVDF coating, polishing, etc.

◆ Excellent performance. National standard quality, the content of various chemical components and the composition of each component meet national standards, the material is stable, the performance is superior, and the cost performance is particularly high. There will be no knife sticking or breaking in the cutting process.

◆ Good stability. Made of raw aluminum ingots, the internal components of the aluminum plate are dense and uniform, the hardness of the whole plate is uniform, the mechanical properties are stable, the precision is high, and the performance is good.

◆ Good surface quality. The 6063 aluminum plate has a good plate shape, a bright and flat surface, no obvious oxide layer, no obvious defects such as sand holes, pores, and black spots.

FLAIT ALUMINUM is a professional manufacturer of aluminum plates, aluminum strips, and aluminum foils. It has rich experience in aluminum plate processing and manufacturing. The company can produce 6063-t6 aluminum plates, pre-stretched 6063-t651 aluminum plates, 6063 ultra-flat plates, 6063 quenched plates and other aluminum plates in various states. The specifications can be customized and free samples are provided. Welcome to contact us! Click to Order

Tags:6063 aluminum plate