- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

Hydrophilic Aluminum Foil for Air Conditioner

Extended service life

Extended service life Anti-corrosion

Anti-corrosion Dust-proof

Dust-proof Anti-odor

Anti-odor Anti-fungal

Anti-fungal Reduce noise

Reduce noise

Air conditioner aluminum foil including bare aluminum foil, blue and gold hydrophilic aluminum foil, which also called aluminum fin stock foil. Air conditioner aluminum foil is mainly used in the production of heat exchanger fins, such as condensers and evaporators of air conditioner, refrigerator, automotive, etc. Hydrophilic aluminum foil can be surface-coated, usually blue and gold. The hydrophilic layer can make the moisture in the hot air condense on the heat exchanger fins and the water droplets can easily spread and flow down the sheet. This can avoid affecting the heat exchanger due to the “bridging” of water droplets between the heat exchanger fins. The ventilation effect increases the heat exchange rate by 5%. The main aluminum foils for air conditioning are: 8006 hydrophilic aluminum foil, 8011 hydrophilic aluminum foil, 3102 hydrophilic aluminum foil, 1100 hydrophilic aluminum foil, etc.

| Alloy | Temper | Thickness (mm) | Width (mm) | Core ID (mm) | Color | Core Material |

| 1100 3102 8011 8006 |

O/HO H22 H24 H26 H18 |

0.08-0.20 | 100-1400 | ¢75,¢150, ¢200,¢300, ¢505 |

blue, gold,green, rose red, etc. |

Paper tube, aluminum |

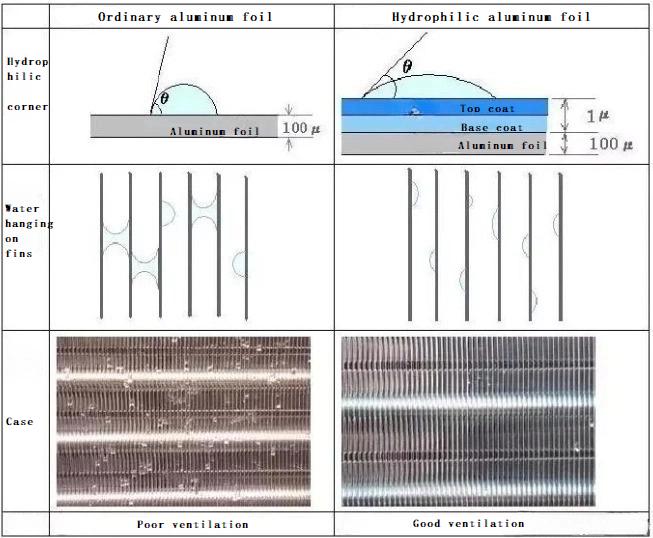

Hydrophilicity of hydrophilic aluminum foil: The surface of aluminum foil coated with hydrophilic coating has a strong affinity for water. Condensed water spreads quickly on the fins and is not easy to form “water bridges”, so the ventilation effect is good when the air conditioner is running. A measure of hydrophilicity is called the hydrophilic angle.

Comparison of ventilation conditions between hydrophilic aluminum foil and ordinary aluminum foil

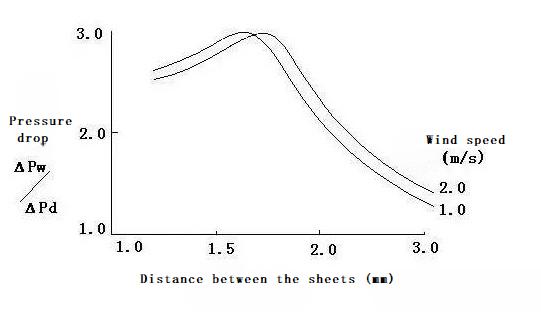

For ordinary / non-hydrophilic aluminum foil: the smaller the distance between the sheets, the larger the pressure drop ratio, and the lower the heat exchange efficiency of the evaporator. Taking a heat exchanger with a row distance of 25.4 as an example, the change curve of the pressure drop ratio when different wind speeds pass through is measured as follows:

*Note: Pressure drop ratio refers to the pressure difference ΔPw before and after the heat exchanger passes through a certain flow rate of air in a humid state, and the ratio of the pressure difference ΔPd before and after airflow with a certain flow rate passes through in a dry state. The larger the pressure drop ratio, the greater the resistance the airflow encounters when passing through the heat exchanger.

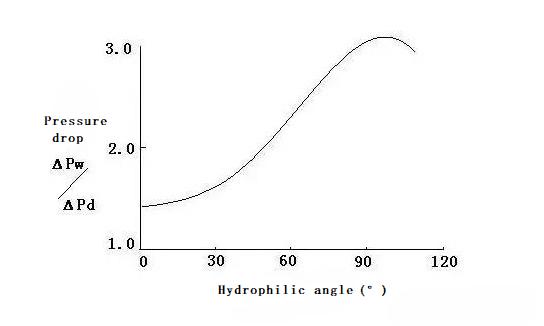

For hydrophilic coated aluminum foil fins: the smaller the contact angle, the lower the pressure drop ratio, and the better the evaporator heat transfer efficiency. Using a set of coated aluminum foils with different hydrophilic angles, the pressure drop ratio curve is obtained as follows:

Original Source: https://www.flait-aluminum.com/Hydrophilic-Aluminum-Foil-For-Air-Conditioner-Heat-Exchanger.html