- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

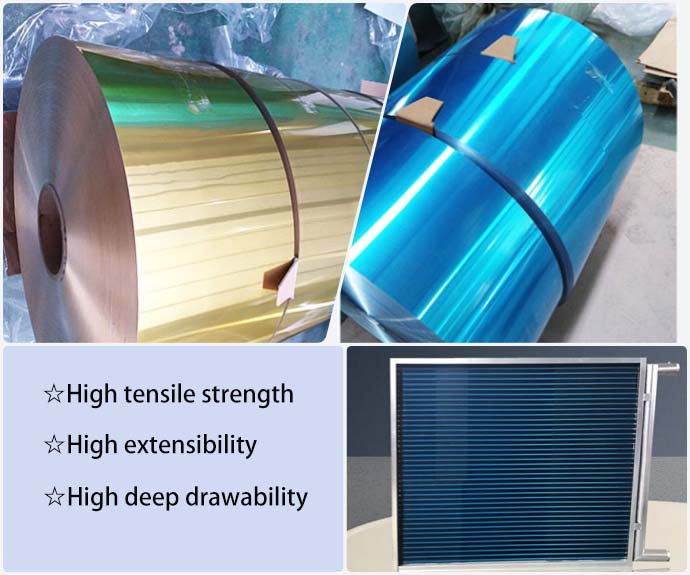

8011 and 8006 Aluminum foil for air conditioning heat exchangers is mainly used as components such as radiator aluminum foil fins and air supply ducts. The processing method used for fins is mainly deep drawing, which requires the aluminum foil to have high plasticity and large elongation under high strength. The punching diameter of radiator fins is generally Φ9.52mm, and the flange height is ≥1.7mm; the alloys used are generally: 8011 aluminum foil and 8006 aluminum foil; the tempers are: O/HO, H22 and H24; 8011 8006 aluminum foil commonly used colors for air conditioning heat exchangers are: Blue, Gold, Bare.

Product: Hydrophilic aluminum foil for air conditioner finstock

Alloys: 8006/8011/3102/1100

Tempers: O/HO, H22, H24, H26, H18

Thickness: 0.08-0.20mm

Width: 100-1250mm

Length: C

Color: Blue, gold/golden, bare/plain, green, rose red, etc.

Coil ID: ¢75,¢150,¢200,¢300,¢505

Sleeve: Aluminum, carbon, steel

Packaging: wooden pallets

Standards: EN, ASTM, DIN, GB/T-3198

Application: Air conditioner, condenser, heat exchanger and evaporator etc.

| Chemical Composition | |||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | AL | |

| Single | Total | ||||||||||

| 8011 | 0.5-0.9 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | 0.08 | 0.05 | 0.15 | Balance |

| 8006 | 0.4 | 1.2-2.0 | 0.3 | 0.3-1.0 | 0.1 | – | 0.1 | – | 0.05 | 0.15 | Balance |

Commonly used thickness of 8011 8006 aluminum foil for air conditioning heat exchangers: 0.1mm~0.20mm.

Mechanical properties: tensile strength ≥100Mpa, elongation ≥25%, cupping value ≥7.5mm.

Air-conditioning aluminum foil is a special material for manufacturing heat exchanger fins for air conditioners. The air-conditioning foil used in the early days was plain foil or bare aluminum foil. In order to improve the surface properties of the plain aluminum foil, before the fins are formed, an anti-corrosive inorganic coating and a hydrophilic organic coating are applied to form a hydrophilic aluminum foil.

Compared with bare aluminum foil, hydrophilic treated aluminum foil is used as a cooling fin, which can effectively eliminate the “water bridge” phenomenon between the fins, thereby reducing the ventilation resistant noise of the air conditioner and reducing the energy consumption of the air conditioner; increasing the heat exchange rate by 5%, improving the anti-corrosion performance of the fins, thereby expanding the environmental adaptability of the air conditioner.

To meet the requirements of miniaturization and personalization of air conditioners, air conditioning aluminum foil must have good formability, its structure and properties must be uniform, good metallurgical quality, uniform aluminum foil thickness, good plate shape, small anisotropy, and tensile strength is required, improvement of elongation and deep drawing properties. The development trend of air conditioning aluminum foil is:

In order to reduce costs, the thickness of high-quality air conditioning foil has been reduced to 0.095mm, and 0.075mm products are also available;

In order to reduce costs, the thickness of high-quality air conditioning foil has been reduced to 0.095mm, and 0.075mm products are also available; The height of the fin flange in the H26 state of commercial air conditioners is close to 2mm, while the height of the fin flange in the H22 state of central air conditioners reaches 3.2mm. This can reduce the number of layers of air conditioner fins and reduce costs;

The height of the fin flange in the H26 state of commercial air conditioners is close to 2mm, while the height of the fin flange in the H22 state of central air conditioners reaches 3.2mm. This can reduce the number of layers of air conditioner fins and reduce costs; The flange height is generally less than 1.3mm, which can meet the requirements for miniaturization and personalization of air conditioners.

The flange height is generally less than 1.3mm, which can meet the requirements for miniaturization and personalization of air conditioners.

Original Source:https://www.flait-aluminum.com/Hydrophilic-Aluminum-Foil-For-Air-Conditioner-Heat-Exchanger.html