- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

For more detailed information including pricing, customization and shipping.

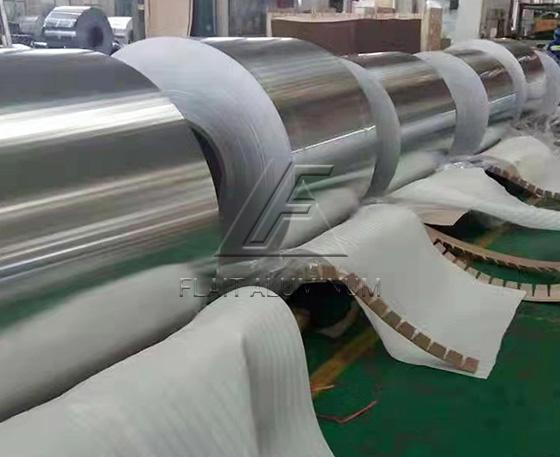

The main elements of 8011 aluminum sheet and foil are Al-Fe-Si, its performance is better than that of pure aluminum foil. It is mainly used in ROPP caps, PP caps, wine lids, red wine bottle caps, whiskey, cosmetic bottle caps, milk powder caps, medical bottle caps, beverage caps, yogurt caps, juice lids, easy-open lids, oral liquids, tea lids and other products. 8011 aluminum sheet and foil has light in weight, food grade, good barrier properties and formability, good deep drawing performance, low ear-making rate, and certain strength after work hardening. 8011 aluminum sheet foil for bottle caps, commonly used tempers are H14/H16/H18, the thickness range is 0.15-0.27mm, the width range is 200-1000mm, the thickness tolerance is ±0.005mm, and the width range tolerance is ±1mm.

8011 aluminum closure material is divided into cast-rolled and hot-rolled, depending on the tempers and needs of different industries:

● 8011-H18 aluminum sheet foil for bottle cap is mainly applied to stamping shallow caps, and casting and rolling can be used.

Production process of 8011-H18 aluminum closure sheet foil: cold rolling - foil rolling - stretch bending and straightening - slitting - packaging, and other processes do not require annealing, so the production process has a short time cycle, and the price is also cheap.

● 8011-H16 aluminum sheet foil for bottle cap is one of hot-rolled aluminum anti-theft cap materials. The tensile strength is 150~165Mpa, the elongation is >2%, the plate surface is smooth, and there are no obvious roll marks, black lines, oil spots, dust inclusions, scratches, bright strips and other defects. The ear making rate is controlled within 3%. The production processes of 8011-H16 aluminum sheet foil for medical bottle caps and wine caps are slightly different. Since wine caps have higher stretching requirements than pharmaceutical caps, there are differences in annealing.

Production process of 8011-H16 aluminum closure sheet foil: cold rolling - foil rolling annealing thickness - annealing - finished foil rolling - stretch bending and straightening - slitting and other processes. After the finished roll is produced, it must go through multiple processes such as cutting with a flattening machine, painting, drying, multiple stampings, and anti-counterfeiting markings to produce qualified bottle cap materials.

| Alloy | 8011 Aluminum foil sheet |

| Tempers | H14, H24, H16, H26, H18 |

| Thickness (mm) | 0.15-0.50 |

| Width (mm) | 50-1500 |

| Length (mm) | 500-2000 |

| ID Diameter (mm) | 75, 150, 200, 300, 350, 405, 505 |

| Surface Treatment | 1. Plain mill finish aluminum strip 2. DOS oil lubricated finish 3. Chromated finish 4. One side golden/white/red/blue/black,etc other colored, other side protective lacquered 5. Both sides clear epoxy varnish. |

| Application | ROPP caps, PP caps, wine lids, red wine bottle caps, whiskey, cosmetic bottle caps, milk powder caps, medical bottle caps, beverage caps, yogurt caps, juice lids, easy-open lids, oral liquids, tea lids, etc. |

| Delivery time | 25-30 days |

| Package | Export package |

| Samples | Available |

Chemical composition of 8011 aluminum foil sheet for bottle caps

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Others | Al |

| 8011 | 0.5-0.9 | 0.6-1.0 | ≤0.10 | ≤0.20 | ≤0.05 | ≤0.10 | ≤0.08 | ≤0.15 | Remainder |

Mechanical properties of 8011 aluminum foil sheet for bottle caps

| Alloy | Temper | Thickness (mm) |

Tensile strength (Rm/Mpa) |

Elongation (%) |

Earing rate (%) |

| 8011 | H14 | 0.15-0.5 | 125-165 | 2 | 3 |

| 8011 | H16 | 0.15-0.5 | 130-165 | 1 | 3 |

| 8011 | H18 | 0.2-0.5 | ≥165 | 1 | 3 |

Excellent Formability

Excellent Formability8011 aluminum sheet has excellent formability, which means it can be easily shaped and formed into the desired cap diversified designs.

Good Deep-Drawability

Good Deep-Drawability8011 aluminum sheet exhibits superior deep-drawability. It can undergo the deep-drawing process without cracking or wrinkling, resulting in seamless and well-formed caps.

Great Corrosion Resistance

Great Corrosion Resistance8011 aluminum sheet offers excellent corrosion resistance, ensuring the caps remain intact and provide a protective barrier for the contents of the sealed containers. This is especially important for caps used in packaging beverages and other sensitive products.

Good Heat Resistance

Good Heat Resistance8011 aluminum sheet exhibits good heat resistance, allowing it to withstand high-temperature processes such as sterilization.

Compatibility with PP

Compatibility with PPPP is a commonly used material for caps, and 8011 aluminum sheet is compatible with PP. This compatibility ensures a secure bond between the aluminum cap and the PP liner, providing reliable sealing and preventing leakage.

Good protection function

Good protection function8011 Aluminum bottle caps have good barrier properties, which can avoid contamination of products by microorganisms, moisture or gas, thereby ensuring safe storage of products, extending shelf life and validity, and ensuring flavor and taste.

Convenient to open and close

Convenient to open and closeAluminum bottle caps are easy to open and close. No auxiliary tools are needed, just turn it gently to open. Aluminum bottle caps ensure convenience, reliability and safety whenever they are opened or closed.

Anti-counterfeiting properties

Anti-counterfeiting propertiesAluminum bottle caps can be produced in batches and at low cost, and have a high cost performance. With the application of innovative technology, different types of anti-theft and anti-counterfeiting designs are used on aluminum bottle caps. If the wine bottle has been opened, the connecting lines on the bottle cap will break, making it very easy for consumers to identify.

Customizability

Customizability8011 aluminum sheet can be easily customized in terms of size, thickness, and surface finish, allowing manufacturers to produce caps that meet specific design requirements and branding needs.

Lightweight

Lightweight8011 aluminum is inherently lightweight. The use of lightweight materials in caps helps reduce the overall weight of packaging, leading to cost savings in transportation and improved sustainability.

Recyclability

RecyclabilityAluminum is highly recyclable, and 8011 aluminum sheet caps can be easily collected, recycled, and repurposed. This supports sustainability efforts by reducing waste and conserving resources.