- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

Aluminum bottle caps are common packaging materials in life. They are mainly used for the packaging of beverages, alcoholic beverages, and pharmaceutical bottles. They have the advantages of good sealing and high safety. Aluminum bottle caps are generally made of 1, 3, and 8 series aluminum foils. Since aluminum caps are mostly processed on production lines with a high degree of automation, the performance requirements of the materials are relatively high.

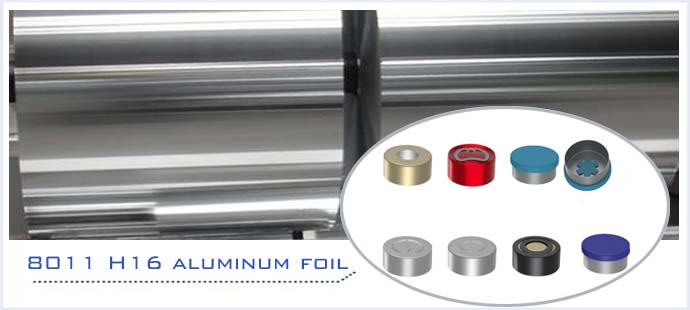

8011 aluminum foil is one of the commonly used aluminum bottle cap materials, among which 8011 H16 aluminum foil is often used for vial seals, and is often seen in pharmaceutical bottle caps, such as oral liquid bottle caps. The raw material of the pharmaceutical cap is 8011 H16 aluminum foil, which is processed into bottle caps through special processes. The aluminum cap for medicine is thin and easy to open. It is widely used in pharmaceutical oral liquids. The aluminum cap also plays its superiority in the sealing of bottled liquids.

◆ Alloy: 8011 Aluminum Foil

◆ Temper: H16

◆ Thickness: 0.15-0.27mm

◆ Width: 330-1000mm

◆ Length: C

◆ Applications: wine caps, easy-pull caps, medicine bottle caps, milk powder easy-tear caps, etc.

8011 aluminum foil has high performance requirements, and is food grade, cleanly degreased, has few holes, good product shape, good deep drawing performance, and low ear-making rate. Only in this way can the quality be ensured in later use.

1. Lightweight and corrosion-resistant.

1. Lightweight and corrosion-resistant. 2. Good sealing.

2. Good sealing. 3. Easy to open.

3. Easy to open. 4. Low cost.

4. Low cost. 5. Hygienic and safe.

5. Hygienic and safe.8011 H16 bottle cap material process must go through cold rolling-foil rolling annealing thickness-annealing-foil rolling finished product-stretching and bending correction-slitting and other processes. After the finished roll is produced, it must go through the process of cutting by the flattening machine, painting, drying, multiple stamping, anti-counterfeiting labeling, and finally produce qualified bottle cap materials.

Original Source:Aluminum Sheet Coil for Cap Closure

Tags:8011 aluminum foil