- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

▶Excellent hydrophilicity & corrosion resistance

▶Good formability

▶Strong resistance to stamping oil, solvent resistance, and heat resistance

▶Low air flow resistance, heat exchange rate can be increased by 10%-15%

▶Smooth surface, beautiful appearance

▶Extended service life

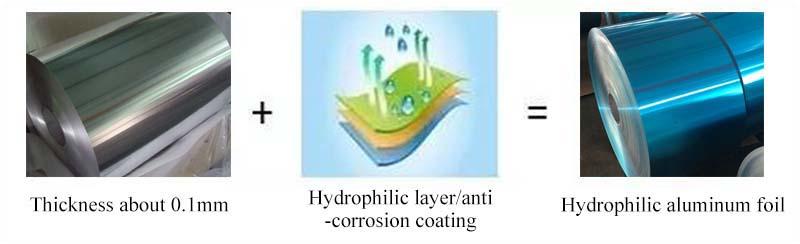

8011 and 8006 air conditioner heat exchanger aluminum foils are coated with a hydrophilic layer on the surface of the aluminum foil to increase its corrosion resistance and hydrophilicity. The hydrophilic layer can make the water droplets condensed on the heat exchanger plate in the hot air spread easily and flow down along the sheet, so as to avoid the “bridge” between the water droplets between the heat exchanger plates affecting the ventilation effect of the heat exchanger, thereby increasing the heat exchange rate by 10%-15%.

8011 and 8006 air conditioner heat exchanger aluminum foils, commonly used tempers are O/HO/H22, and commonly used colors are Bare/Plain/Blue/Gold; air conditioner radiator aluminum foil is the main raw material for heat exchanger plates in air conditioners, and is widely used in refrigeration equipment such as household/commercial air conditioners, refrigerators, and car air conditioners.

Colors: blue hydrophilic aluminum foil, gold hydrophilic aluminum foil, black hydrophilic aluminum foil, bronze hydrophilic aluminum foil, bare/plain aluminum foil

Aluminum alloy grades: 8011, 8006, 3102, 3105, 1100

Specifications: thickness 0.08mm~0.5mm; width 15mm~1000mm

Inner diameter of roll: 75mm, 150mm, 300mm, 400mm, 500mm

Application: air conditioners, refrigerators, evaporators, condensers, air conditioner radiators, heat exchanger, etc.

Aluminum foil for air conditioner heat exchanger/hydrophilic aluminum foil is a new type of aluminum foil product with relatively low density. Generally speaking, the density of hydrophilic aluminum foil is about 2.6~2.8g/cm³, which is lower than that of ordinary aluminum foil. Hydrophilic aluminum foil is a product with hydrophilic surface and specially treated, its special surface coating can make it have better performance in absorbing water. Due to the weight of aluminum foil itself is light, hydrophilic aluminum foil is more convenient in use, which can meet people’s requirements for high quality and high efficiency, is a material suitable for wide application.

Hydrophilic aluminum foil is a hydrophilic treatment of aluminum foil, through special process treatment, a hydrophilic layer is coated on its surface. Condensed water will quickly disperse on the hydrophilic aluminum foil and will not condense into water droplets, which increases the heat exchange area, speeds up the cooling and heating speed, and effectively avoids the noise caused by condensed water blocking the air flow.

After degreasing, washing and drying, the aluminum foil of the air conditioner heat exchanger is coated with special coating on both surfaces. After drying and cooling, it becomes a highly hydrophilic and corrosion-resistant material, which can effectively reduce the adhesion and contamination of the aluminum foil surface during production and use. Hydrophilic aluminum foil can effectively extend the service life of the air conditioner by 5-10 years.

Original Source:https://www.flait-aluminum.com/Hydrophilic-Aluminum-Foil-For-Air-Conditioner-Heat-Exchanger.html