- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

For more detailed information including pricing, customization and shipping.

Aluminum jacketing insulation coil roll (is also called aluminum cladding roll, insulation aluminum coil roll, thermal insulation aluminum roll, heat insulation aluminum roll) is a protective covering, often used in equipment insulation and pipe insulation to prevent damage and improve energy efficiency. Aluminum insulation jacketing roll is made from aluminum sheet that's precision cut and rolled to fit tightly to the insulation. Aluminum insulation roll enhance insulation properties by providing a barrier against moisture, UV rays and mechanical damage. It is available in mill finish, smooth, stucco embossed surface finishes, with moisture barrier consisting of polysurlyn and composite kraft paper.

◆ The typical products of aluminum jacketing are: 1050/1060/1100 pure aluminum jacketing insulation roll, 3003/3105 anti-rust aluminum jacketing insulation roll, 5005/5052 anti-rust and corrosion-resistant aluminum jacketing insulation roll. Aluminum jacketing roll with beautiful appearance, bright and clean, is widely used in electric power, chemical industry and other industries equipment, tanks, pipeline anticorrosion and heat preservation.

◆ Aluminum Jacketing products can be supplied with a kraft (1 1/2 mil polyethylene) or a 3 mil polysurlyn moisture barrier which is heat and pressure bonded to the interior surface. A moisture barrier helps prevent galvanic corrosion caused by contact of dissimilar metals in the presence of moisture or chemical corrosion caused by installing sheets over damp insulation materials.

◆ The common width of aluminum insulation jacketing coil roll is 1 meter, and the thickness is according to the mechanical needs. The conventional thickness is 0.3, 0.4, 0.5, 0.6, 0.8, 1.0mm. In order to facilitate the construction, the thermal insulation aluminum coil is guided from the large coil to the small roll. The weight of the conventional small roll is 50kg, and some generally weigh no more than 70kg for the convenience of construction. Contact our specialists to start customizing aluminum jacketing that suits your project needs!

Temper: H14,H16,H24,H26,etc.

Temper: H14,H16,H24,H26,etc.

Temper: H14,H16,H24,H26,etc.

1060 Aluminum jacketing insulation coil roll is a pure aluminum, with an aluminum content greater than or equal to 99.6%. It is an ordinary aluminum coil for thermal insulation. It is relatively cheap and has a wide range of applications, such as: waterproofing of ordinary buildings and thermal insulation and rust prevention of municipal pipelines. However, 1060 Aluminum jacketing rolls are not resistant to acid and alkali corrosion, and are not suitable for heat preservation of equipment and pipelines in power plants and chemical plants.

3003 Aluminum jacketing insulation coil roll (also known as anti-rust aluminum coil) is an Al-Mn alloy, with a manganese content of about 1.12, which is good in rust and corrosion resistance. The strength, rust resistance and corrosion resistance of 3003 aluminum coils are higher than 1060 aluminum coils; the price also is higher than1060, which belongs to the mid-end products in the aluminum jacketing insulation roll. It is mostly used for heat preservation of refrigeration equipment, storage tanks, pressure vessels and pipes, heat sinks, etc.

5052 Aluminum jacketing insulation coil roll is Al-Mg alloy, high strength, plasticity, good corrosion resistance, good fatigue relief, and can be welded and processed.It is regarded as a more promising aluminum insulation jacketing coil roll. The price of this series of thermal insulation aluminum coils is higher than 1060 and 3003 aluminum coils. 5052 Aluminum jacketing rolls are used in occasions that have strict requirements on the performance of aluminum coils, such as height, fatigue resistance, corrosion resistance, etc., such as maritime, shipbuilding, chemical industry, electric power, nuclear power, aviation, aerospace and other fields.

◎Surface Finish

Mill Smooth Aluminum Jacketing Insulation Coil

Surface is clean, bright and beautiful

Effect of treating rainwater is good

Surface is smooth to prevent dirt

High reflectivity to sunlight

Stucco Embossed Aluminum Jacketing Coil

Hide small damage and scratches

Good strength, ductility and durability

Reduce reflectivity

Good visual effect

Corrugated Aluminum Jacketing

Hide small damage and scratches

Reduce sunlight reflection

Good rigidity and strength

Great expansion and contraction capacity

◎Types of Moisture Barrier

Polysurlyn Moisture Barrier Aluminum Jacketing Coil

Excellent corrosion resistance

Waterproof and anti-oxidation

Extended service life

Good wear resistance

PolyKraft Paper Aluminum Jacketing Coil

Good anti-corrosion, anti-rust and thermal insulation

Waterproof, anti-oxidation

Good durability

Beautiful surface (Color: khaki)

|

Alloy |

1050, 1060, 1100, 3003, 3105, 5005, 5052, etc. |

|

Temper |

H14, H16, H24, H26 |

|

Thickness |

0.30-1.50mm |

|

Width |

914mm, 1000mm, 1200mm, 1219mm, etc. |

|

Length |

50' (15 meters), 100' (30 meters), 200' (60 meters), 300' (90 meters), Coil (specify lengths), Flat Sheets (cut to length), Cut & Rolled (to specific lengths) |

|

Inner diameter |

75mm, 150mm, 305mm, 405mm, 505mm with or without paper core |

|

Surface treatment |

Mill finish, smooth/plain, stucco embossed, corrugated |

|

Moisture barrier |

Polysurlyn, composite kraft paper |

|

Surface lamination |

Kraft paper laminated |

|

Kraft paper thickness |

About 0.1mm |

|

Polysurlyn thickness |

About 0.076mm (3mil) |

|

Quality standard |

ASTM B209,ISO9001, GB/T3880 |

|

Quantity |

Have ready stock for most common thickness roll small quantity order are acceptable. |

|

Sample |

Available |

|

Aluminum Jacketing for Pipe Insulation |

||||

|

Thickness(inch) |

Thickness(mm) |

Width(mm) |

Length(m) |

Suggested Application |

|

0.012 |

0.3 |

914,1000,1219 |

20,25,30, 60,90 per roll or customized |

OD below 36"(914mm) insulated pipe lines. |

|

0.016 |

0.4 |

914,1000,1219 |

20,25,30, 60,90 per roll or customized |

OD below 36”(914mm)insulated lines. |

|

0.020 |

0.5 |

914,1000,1219 |

20,25,30, 60,90 per roll or customized |

OD below 36”(914mm)insulated lines. |

|

0.024 |

0.6 |

914,1000,1219 |

20,25,30, 60,90 per roll or customized |

OD below 36”-8’(914mm-2.43m)insulated lines & equipment. |

|

0.032 |

0.8 |

914,1000,1219 |

20,25,30, 60,90 per roll or customized |

Special applications where extra thickness and protection is required, such as fabricated tank head covers and other special fabrications. |

|

0.040 |

1.0 |

914,1000,1219 |

20,25,30, 60,90 per roll or customized |

Special applications where heavy mechanical is required. |

|

0.050 |

1.2 |

914,1000,1219 |

20,25,30, 60,90 per roll or customized |

Flat ducts or precipitators. Also recommended for areas subject to high wind conditions. |

The insulation jacketing aluminum coil is very light in weight. Since the specific gravity of aluminum is 2.71 KG/M3, the weight of the aluminum jacket per square meter is very light, which can save a lot of raw materials and reduce costs.

The insulation jacketing aluminum coil is very light in weight. Since the specific gravity of aluminum is 2.71 KG/M3, the weight of the aluminum jacket per square meter is very light, which can save a lot of raw materials and reduce costs. The appearance of the thermal insulation aluminum coil is smooth and beautiful, and there is no need to worry about the phenomenon of rust on the product in the later stage.

The appearance of the thermal insulation aluminum coil is smooth and beautiful, and there is no need to worry about the phenomenon of rust on the product in the later stage. The aluminum jacketing coil is convenient for construction and can improve work efficiency. Aluminum has relatively high plasticity and can be easily bent and wound, which greatly improves work efficiency.

The aluminum jacketing coil is convenient for construction and can improve work efficiency. Aluminum has relatively high plasticity and can be easily bent and wound, which greatly improves work efficiency. The insulation jacketing aluminum coil has good anti-rust, waterproof and anti-corrosion characteristics.

The insulation jacketing aluminum coil has good anti-rust, waterproof and anti-corrosion characteristics. The aluminum jacketing coil is easy to process and form, the construction is convenient and fast, and the labor intensity of the construction personnel is reduced.

The aluminum jacketing coil is easy to process and form, the construction is convenient and fast, and the labor intensity of the construction personnel is reduced. The recycling value of aluminum jacketing coil is high. The iron sheet will corrode and rot after several years of use, and has almost no recycling value. However, the aluminum coil can be recycled at least 80% because of its corrosion resistance.

The recycling value of aluminum jacketing coil is high. The iron sheet will corrode and rot after several years of use, and has almost no recycling value. However, the aluminum coil can be recycled at least 80% because of its corrosion resistance.

1050/1060/1100 Aluminum insulation jacketing coils are pure aluminum, and have a wide range of applications, such as general building waterproofing, pipe insulation, and anti-rust engineering. But 1000 series aluminum coils are not resistant to acid, alkali and corrosion.

3003 and 3105 Aluminum insulation jacketing coils are recommended for insulation of equipment and pipes in power plants and chemical plants. 3003/3105 Aluminum insulation jacketing coils are made of aluminum manganese aluminum alloy. 3003 aluminum insulation coil, also known as anti-rust aluminum coil, will last longer in use, and is mainly used for heat insulation of refrigeration equipment, storage tanks, pressure vessels and pipes, heat sinks, etc.

5052/5005 Aluminum insulation jacketing coils are aluminum-magnesium alloy and an excellent anti-rust aluminum, have high strength, fatigue resistance, corrosion resistance, etc. which are mostly used in special environments, such as maritime, shipbuilding, chemical industry, electric power, etc.

Aluminum Jacketing is recommended for HVAC, Insulated Piping, Tanks & vessels less than 8 feet in diameter.

Aluminum Jacketing is recommended for HVAC, Insulated Piping, Tanks & vessels less than 8 feet in diameter. Deep corrugated sheets are recommended for diameters greater than 8 feet.

Deep corrugated sheets are recommended for diameters greater than 8 feet. Chemical Plants & Refineries: Distillation columns, tank farms, fractionation units, cokers and ethylene production units.

Chemical Plants & Refineries: Distillation columns, tank farms, fractionation units, cokers and ethylene production units. Paper Mills: Chemical storage tanks, breechings and ducts.

Paper Mills: Chemical storage tanks, breechings and ducts. Steel Mills: Pickle acid tanks, oxygen production units, fuel oil and tar storage tanks.

Steel Mills: Pickle acid tanks, oxygen production units, fuel oil and tar storage tanks. Miscellaneous: Power station, food processing plants, LPG storage units, LNG storage units, sewage and waste water treatment plants.

Miscellaneous: Power station, food processing plants, LPG storage units, LNG storage units, sewage and waste water treatment plants.

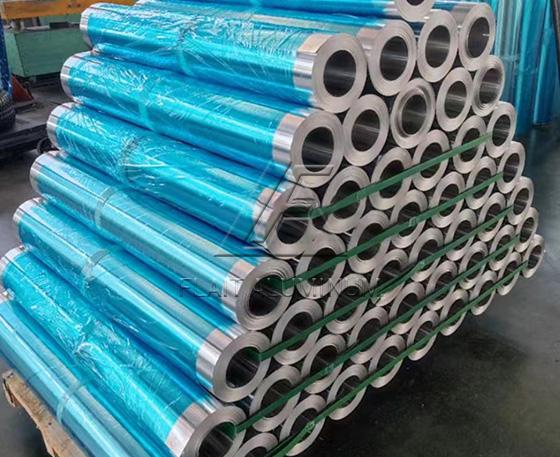

◆Package:

According to the needs of customers, the thermal insulation aluminum skin can be packaged in whole rolls or divided into small rolls. For the convenience of customers' construction and use, please inform us in advance; When dividing into small rolls, the paper core is used to prevent the small rolls from being deformed or bent due to extrusion; the aluminum coil should be sealed with plastic cloth, and the seal should be sealed with transparent tape to prevent water vapor from entering and causing the aluminum coil to corrode and discolor; The outer packaging is tightly packed with a thick paper shell, and a layer of kraft paper can be added between the plastic cloth and the paper shell to increase the protection effect; the packaged aluminum coil is placed on a wooden pallet and reinforced with a steel strip.

◆Transportation:

When loading the vehicle, do not let the aluminum coil be squeezed, especially the small coil, which is prone to bending or collapse, which will affect the normal use; although it is tightly packaged, it is inevitable that the package will be damaged during loading and transportation, so pay attention to the aluminum coil. Do not pour water on the roll to prevent water from entering the aluminum roll; do not place objects on the aluminum roll, especially small rolls without paper cores, which are easily deformed and affect the construction and use.

Flait Aluminum provides many types and specifications of aluminum insulation jacketing roll, which can be customized according to the needs, and the selection range is wide.

We have rich production experience, professional research and development, perfect after-sales system, reasonable configuration of production plan, fast production cycle and timely delivery. We are able to recommend the most suitable and cost-effective materials according to the needs, uses and usage environments of different customers.

Our quotation model is: Shanghai nonferrous metal price SMM + processing cost + transportation cost.