- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

For more detailed information including pricing, customization and shipping.

It is common to use aluminum alloy as the material of bottle cap material. Bottle cap aluminum material is mainly used for packaging of wine, food and beverage, cosmetics, etc. The main purpose of aluminum bottle cap material is related to people's eating and use, so the requirements of product are relatively high, and it is important to choose high-quality manufacturer to buy aluminum cap materials.

The main products of aluminum for bottle caps are 1xxx, 3xxx, 8xxx series aluminum alloy plates, including 8011 aluminum plate, 3105 aluminum plate, 1060 aluminum plate, 3104 aluminum plate, 5052 aluminum plate, and so on; tempers are H14, H16, H18, etc.; the thickness is 0.15-0.5; and the width is 200-1600mm. Aluminum alloy cap material not only has good deep drawing performance, tensile performance, ear forming rate and corrosion resistance, but also has a certain baking strength after multiple color printing and curing. We control the material composition, rolling temperature and time, annealing temperature to produce the best material to meet the performance needs of customers, such as opening capability and earing rate. Aluminum alloys for cap materials are widely used in cap packaging for various wine bottles, beverage bottles, medicinal bottles, and cosmetics.

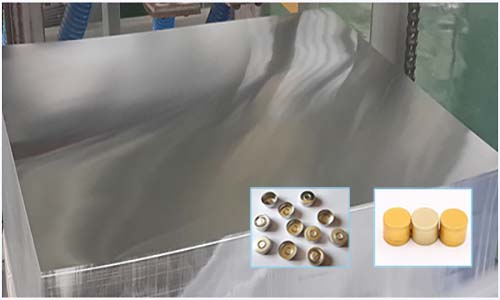

8011 Aluminum sheet plate for bottle caps has good deep drawing performance, low ear making rate, and certain strength after work hardening. Usually 8011 aluminum sheet is used to make ROPP caps, PP caps, anti-theft caps in rolls, anti-theft caps, aluminum bottle caps, aluminum screw caps, tear-off caps, flip caps. In addition, 8011 aluminum sheet is an ideal material for producing PP caps for whiskey and other beverage bottles. 8011 aluminum sheet has light weight, good barrier property and formability.

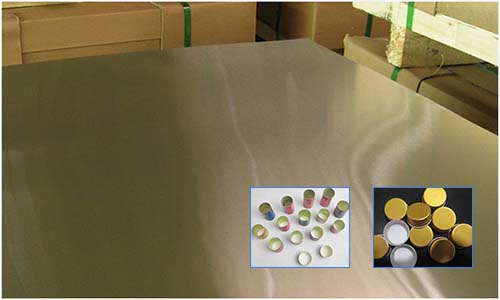

3105 Aluminum sheet plate for bottle caps has good anti-rust performance and good deep drawing effect. Compared with the 8011 aluminum plate for bottle caps, the 3105 aluminum sheet for screw caps has enough strength and can withstand larger gas pressure. 3105 aluminum sheet is widely used to make screw caps for gas liquid bottle, such as soda water, carbonated wine and champagne. Also, the 3105 aluminum sheet for bottle caps can be printed in different colors and decorated with different styles of wine bottle caps and other bottle caps after being treated with chromium phosphate or DOS coating.

5052 Aluminum sheet strip for bottle caps of cans. The hardness of magnesium is better than other alloys, which ensures the good shape of cans during transportation. Also, it is the most widely used rust-proof aluminum. The material of the pull ring can cover is generally processed by 5052 and 5182 aluminum plates, and the pull ring handle is also used 5182 aluminum alloy. 5052 / 5182-H19 aluminum plate for bottle caps has low density, light weight, smooth surface, good hand feeling, flexible deformation after stamping, and is not easy to crack. The most important thing is that it is environmentally friendly, easy to recycle and reusable.

1060 Aluminum sheet coil for bottle caps has high elongation, tensile strength, excellent electrical conductivity, high formability, and can meet processing requirements (stamping, stretching) requirements. The bottle cap is made by combining 1060 aluminum plate and plastic. Since the aluminum-plastic assembly will be in contact with the liquid in the bottle, most of them are used in the cosmetics industry, and some are used in the pharmaceutical industry (sealed caps for injection bottles). 1060-H24 aluminum plate for bottle caps is mainly used for wine, beverages (with or without gas) and medical care products, and can meet the special requirements of high-temperature cooking and sterilization.

Tempers: O, H22, H24

Applications: Bottle caps for wine, beverages

Tempers: H12

Applications: Cosmetic aluminum lids

Tempers: H14,H24,H16,H26,H18

Applications: Beverage and pharmaceutical closures

Tempers: H14,H24,H16,H26,H18

Applications: ROPP caps, PP caps, wine lids

Tempers: H14,H18,H19

Applications: Can body,can lids and pull rings

The aluminum plate used for bottle cap material has good tensile properties, ear forming rate and corrosion resistance.

The aluminum plate used for bottle cap material has good tensile properties, ear forming rate and corrosion resistance. The surface of the aluminum plate is free from oil stains, dents, scratches, stains, inclusions, oxide discoloration, fractures, corrosion, rolling marks, etc.

The surface of the aluminum plate is free from oil stains, dents, scratches, stains, inclusions, oxide discoloration, fractures, corrosion, rolling marks, etc. Compared with plastic bottle caps, aluminum bottle caps not only have better performance, but also have low cost, no pollution, and can be recycled.

Compared with plastic bottle caps, aluminum bottle caps not only have better performance, but also have low cost, no pollution, and can be recycled.

|

Cap material (aluminum plate) |

|||||

|

Alloy |

1060 |

8011 |

3003 |

3105 |

5052 |

|

Temper |

O,H22 |

H14,H24,H16 H26,H18 |

H14,H24 H16,H26,H18 |

H14,H24,H16 H26,H18 |

H18,H19 |

|

Thickness |

0.15-0.5mm |

||||

|

Width |

500-2500mm |

||||

|

Rolling Process |

CC/DC |

||||

|

Surface Treatment |

1. Plain mill finish aluminum strip 2. DOS oil lubricated finish 3. Chromated finish 4. One side golden/white/red/blue/black,etc other colored, other side protective lacquered 5. both sides clear/transparent lacquered |

||||

|

Application |

Bottle caps, aluminum liquid caps, red wine caps, anti-theft caps, perfume caps, skin care product caps, cosmetic caps, oil caps, aluminum-plastic composite caps for oral liquid, aluminum-plastic caps for infusion bottles, etc. |

||||

|

Delivery time |

25-30 days |

||||

|

Package |

Export package |

||||

|

Samples |

Available |

||||

| Specification Tolerance Range(mm) | ||||||

| Thickness | Thickness Tolerance | Width Tolerance | Length Tolerance | Diagonal Tolerance | Flatness | |

| ≤500mm | >500mm | |||||

| 0.15-0.48mm | -/+ 0.01mm | -/+ 1mm | -/+ 2mm | -0/+1mm | ≤1mm | ≤5mm/2m |

| <3 waves/m | ||||||

|

Chemical Composition Wt(%) |

|||||||||

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Zn |

Ti |

Others |

Al |

|

A1060 |

≤0.25 |

≤0.35 |

≤0.05 |

≤0.03 |

≤0.03 |

≤0.05 |

≤0.03 |

0.03 |

Remainder |

|

A8011 |

0.5-0.9 |

0.6-1.0 |

≤0.10 |

≤0.20 |

≤0.05 |

≤0.10 |

≤0.08 |

≤0.15 |

Remainder |

|

A3003 |

≤0.6 |

≤0.4 |

0.05-0.2 |

1.0-1.5 |

- |

≤0.10 |

≤0.10 |

≤0.15 |

Remainder |

|

A3105 |

≤0.6 |

≤0.7 |

≤0.3 |

0.3-0.8 |

0.2-0.8 |

≤0.40 |

≤0.10 |

≤0.15 |

Remainder |

|

A5052 |

≤0.25 |

≤0.4 |

≤0.1 |

≤0.1 |

2.2-2.8 |

0.1 |

- |

≤0.15 |

Remainder |

|

Mechanical Properties |

|||||

|

Alloy |

Temper |

Thickness(mm) |

Tensile strength(Rm/Mpa) |

Elongation(%) |

Earing ratio (%) |

|

1060 |

O |

0.15-0.5 |

55-95 |

15 |

6 |

|

1060 |

H22 |

0.4-0.5 |

75-110 |

6 |

5 |

|

8011 |

H14 |

0.15-0.5 |

125-165 |

2 |

3 |

|

8011 |

H16 |

0.15-0.5 |

130-165 |

1 |

3 |

|

8011 |

H18 |

0.2-0.5 |

≥165 |

1 |

3 |

|

3003 |

H14,H24 |

0.2-0.5 |

145-185 |

2 |

4 |

|

3003 |

H16,H26 |

0.2-0.5 |

170-210 |

1 |

4 |

|

3003 |

H18 |

0.15-0.5 |

≥185 |

1 |

4 |

|

3105 |

H14,H24 |

0.2-0.5 |

150-200 |

2 |

4 |

|

3105 |

H16,H26 |

0.2-0.5 |

175-225 |

1 |

4 |

|

3105 |

H18 |

0.2-0.5 |

≥195 |

1 |

4 |

|

5052 |

H18 |

0.2-0.5 |

280-320 |

3 |

4 |

|

5052 |

H19 |

0.2-0.5 |

≥285 |

2 |

4 |