- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

For more detailed information including pricing, customization and shipping.

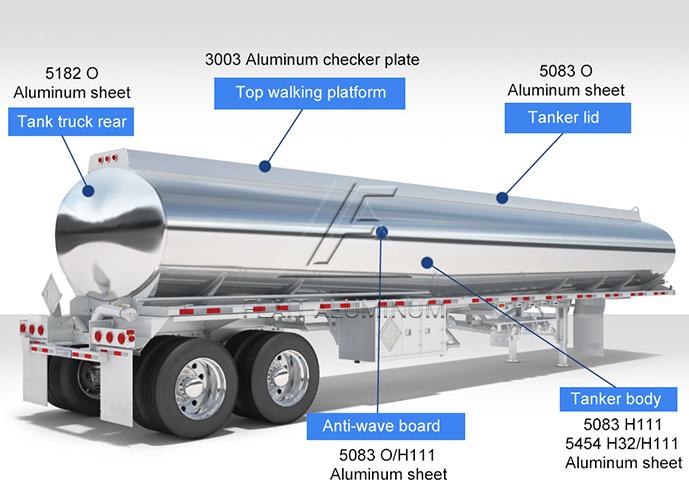

The tanker is a transport vehicle with a tank-shaped body, which is used to transport various liquids, liquefied gases, and powdered goods. Aluminum tank trucks are lighter in weight than carbon steel tank trucks, which reduces fuel consumption and tire wear during transportation, thereby reducing daily operating and maintenance costs. Aluminum alloy has strong corrosion resistance and improves the service life of tank trucks, also it has the advantages of recyclability and high recovery rate.

The main component of the 5 series aluminum plate for oil tank truck is magnesium, and the content is between 3% and 5%. Also known as aluminum-magnesium alloy. Tank truck aluminum plate can be used for continuous casting and rolling, so it can be used for oxidation and deep processing. 5*** series tanker aluminum plate has excellent corrosion resistance and welding performance, and is widely used in oil tanker, gas tanker, cement tanker, etc. The main aluminum sheets plates for tank truck are:

5083 Aluminum sheet plate for tank truck is the most widely used aluminum alloy in the manufacture of tanker. The two commonly used tempers for tanker body are 5083-H111 and 5083-O.

5083-O aluminum sheet plate is annealed status and soft, suitable for bending, used for tank truck heads, lid and anti-wave board.

5083-H111 aluminum sheet plate has high strength, good plasticity, and can withstand certain impacts and vibrations, and is often used in tank truck bodies.

5083-H32 aluminum sheet plate has the strength and hardness lower than 5083-H111, can also be used to make the body of tank trucks, is usually suitable for occasions with small pressure and load.

5083-H321 aluminum sheet plate has excellent resistance to stress corrosion cracking and high-strength, is used in high-pressure environments, like the liquid level gauge, air inlet and other parts of oil tank trucks.

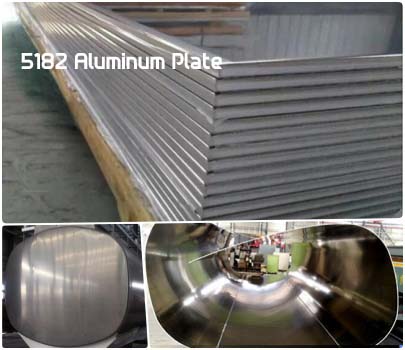

5182 Aluminum sheet plate for oil tanker has high tensile strength and elongation, exceptional durability and corrosion resistance, excellent welding performance.

When 5182 aluminum alloy is used for welding, the mechanical properties in welding can reach the minimum values specified for the base metal. Under the same diameter, the thickness of the aluminum tank truck made of 5182 aluminum plate can be 0.5mm - 1mm thinner than that of 5083 alloy.

5182 Aluminum sheet plate is commonly used in the manufacturing of fuel tankers or tank trailers.

5454 Aluminum sheet plate for tank truck is a typical anti-rust aluminum with high strength, because of its strong corrosion resistance, it is especially suitable for aluminum-magnesium alloy tanker used under high temperature conditions.

5454-H32 Aluminum plate is the common temper of 5454 alloy, suitable for use under high temperature conditions. Surface abrasion resistance makes it the best material for powder tankers.

5454-H32 aluminum plate can still maintain better corrosion resistance and strength than other alloys when the long-term use temperature reaches 65-170°C. In addition, the internal temperature of the aluminum tank truck made of 5454 aluminum plate is more stable.

5754 Aluminum sheet plate for tank truck has good anti-rust and corrosion resistance, no color difference on the anodized surface, excellent processability, high strength and weldability.

The commonly used tempers of 5754 aluminum plate are 5754-H111, H22, H12, H14, H114, etc.

5754 aluminum sheet plate in different heat treatment tempers is the main material used in the automobile manufacturing industry (car doors, molds, seals) and the production of tank cars.

It is widely used in welded structures, storage tanks, pressure vessels, ship structures and offshore installations, automobile manufacturing, and tank trucks.

5052 Aluminum sheet plate for tank truck is the most widely used antirust aluminum, is mainly used for high requirements, plasticity and good weldability, low load parts working in liquid or gaseous medium, such as tank truck fuel tank, gasoline or lubricating oil conduit, various liquid containers and other small parts made by deep drawing.

Tempers: O/HO, H111

Applications: Tank body, wave shields,tank head

Tempers: O/HO, H112, H32

Applications: Tank truck rear

Tempers: O, H32, H111

Applications: Tank body

Tempers: H111, H22, H12, H14, H114

Applications: Tank body, Fuel tank

Tempers: O/HO, H112, H32

Applications: Fuel tank

Tempers: O/HO, H14

Applications: Stairs, walking platforms

|

Alloy |

Temper |

Thickness(mm) |

Width(mm) |

Length(mm) |

|

5083 |

O, H111, H112, H114, H116, H32, etc. |

4.0-8.0 |

1000-2650 |

500-16000 |

|

5052 |

4.0-8.0 |

1000-2650 |

500-16000 |

|

|

5754 |

4.0-8.0 |

1000-2650 |

500-16000 |

|

|

5454 |

4.0-8.0 |

1000-2650 |

500-16000 |

|

|

5182 |

4.0-8.0 |

1000-2650 |

500-16000 |

|

|

Surface |

Smooth surface, bright surface, mirror reflective surface |

|||

|

Standards |

GB/T 3880, EN14286, EN485, ASTM B209, or according to customer's special requirements |

|||

Chemical composition of Aluminum Plate for Tank Truck

|

Alloys |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Other(%) |

|

|

Unit |

Total |

|||||||||

|

5083 |

0.20 |

0.35 |

0.15 |

0.20-0.50 |

4.0-5.0 |

0.10 |

0.25 |

0.10 |

0.05 |

0.15 |

|

5052 |

0.25 |

0.40 |

0.10 |

0.10 |

2.2-2.8 |

0.15-0.35 |

0.10 |

- |

0.05 |

0.15 |

|

5754 |

0.40 |

0.40 |

0.10 |

0.10 |

2.6-3.6 |

0.30 |

0.20 |

0.15 |

0.05 |

0.15 |

|

5454 |

0.25 |

0.40 |

0.10 |

0.10 |

2.4-3.0 |

0.05-0.20 |

0.25 |

0.20 |

0.05 |

0.15 |

|

5182 |

0.20 |

0.35 |

0.15 |

0.15 |

4.0-5.0 |

0.10 |

0.25 |

0.10 |

0.05 |

0.15 |

Mechanical character of Aluminum Plate for Tank Truck

|

Alloys |

Temper |

Rm(Mpa) |

Rp.02(Mpa) |

Elongation(%) |

|

5083 |

O/H111 |

≥275 |

≥125 |

≥15 |

|

|

H112 |

≥275 |

≥125 |

≥12 |

|

5052 |

O/H111 |

170-215 |

≥65 |

≥16 |

|

|

H112 |

≥190 |

≥80 |

≥7 |

|

5754 |

O/H111 |

190-240 |

≥80 |

≥16 |

|

|

H112 |

≥190 |

≥80 |

≥7 |

|

5454 |

H32 |

≥250 |

≥180 |

≥8 |

|

5182 |

O/H111 |

≥280 |

≥125 |

≥26 |

Oil tanker truck aluminum sheets have good plasticity, is easy to process, good ductility and has excellent forming performance.

Oil tanker truck aluminum sheets have good plasticity, is easy to process, good ductility and has excellent forming performance. Strong weldability, can be gas welding, arc welding, contact spot welding and wire welding.

Strong weldability, can be gas welding, arc welding, contact spot welding and wire welding. Oil tanker truck aluminum plates have high strength, corrosion resistance, wear resistance and rust resistance, which can improve the corrosion resistance of the tank body and extend the life of the car body.

Oil tanker truck aluminum plates have high strength, corrosion resistance, wear resistance and rust resistance, which can improve the corrosion resistance of the tank body and extend the life of the car body. Plate shape, size accuracy and surface quality are high.

Plate shape, size accuracy and surface quality are high. The recovery rate of oil tanker truck aluminum sheet is high, which is more economical and environmentally friendly.

The recovery rate of oil tanker truck aluminum sheet is high, which is more economical and environmentally friendly.