- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

Anodized Aluminum and Pre-painted Aluminum are both commonly used surface treatments for aluminum alloys. Both Anodized Aluminum and Pre-painted Aluminum are widely used in the field of architectural decoration, but there are still some differences between them.

1. Different processes

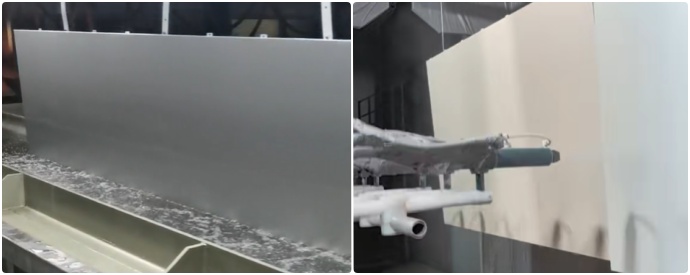

Anodized aluminum is a method of forming an oxide layer on the surface of aluminum alloy through electrolysis reaction. When current is passed through the electrolyte, the surface of the aluminum alloy will oxidize, forming a hard oxide layer.

Pre-painted aluminum is a method of spraying paint onto the metal surface. The sprayed paint will form a protective film after drying on the surface to prevent the aluminum alloy from being oxidized, corroded and worn. Commonly used spray coating materials include PE (Polyester) and PVDF (Polyvinylidene Fluoride).

2.Durability is different

The anodized film is formed through a displacement reaction on the metal surface. The hardness and density of the film are relatively high, so it has good durability. The paint has poor durability and is easily peeled off by scratches, chemicals and direct sunlight. Generally speaking, anodized aluminum is more weather-resistant, more scratch-resistant and has a longer service life than pre-painted aluminum.

3. Different surface effects

Anodized aluminum can produce various colors on the metal surface, such as black, silver, gold, etc., and its surface texture is very good, smooth to the touch, and has an excellent metallic feel. The surface effect of pre-painted aluminum is not as delicate as anodized aluminum, because the surface is covered with a layer of paint, and the texture is not as good as anodized aluminum, but there are more colors to choose from and the colors are richer than anodized aluminum.

4. Different usage costs

Anodizing is a pollution-free, wastewater-free and pollution-free surface treatment method, but it requires high equipment, process and labor costs. The cost of painting equipment and construction is relatively low, and it can be suitable for large-scale industrial production and small batch production. However, anodized aluminum is easier to maintain than pre-painted aluminum, and the later use cost is almost negligible. However, pre-painted aluminum is not as durable as anodized aluminum, and the coating has the risk of peeling, cracking and fading. Anodized aluminum is more cost-effective when considering durability and maintenance requirements.

5. Different application scenarios

Both Anodized Aluminum and Pre-painted Aluminum can be used in the field of architectural decoration, such as building exterior walls, interior decoration, etc. However, the focus of the two application fields is still different. Anodized aluminum is mainly suitable for scenes that require high surface quality and durability. Such as outdoor applications, industrial machinery and 3C product casings, etc. Pre-painted Aluminum is mainly used in indoor scenes to prevent minor daily scratches and wear. Due to its wide range of colors to choose from, it is more commonly used in furniture, decorative building materials, and roofing systems.

The advantage of anodized aluminum is that it has excellent corrosion resistance and wear resistance. The oxide layer is thick, not easy to be worn and peeled off, and does not require regular maintenance. The disadvantage is that the color and effect of the oxide layer are relatively single, and the treatment process is time-consuming and costly. higher. In addition, the anodized surface may also have defects such as uneven thickness of the oxide layer and bubbles.

The advantages of pre-painted aluminum are various coating colors and effects, fast processing time, and simple operation; the disadvantage is that the coating is thin, easy to wear and leave scratches, and requires regular maintenance. The surface quality of spray painting will be affected by spraying technology and environment, and may have defects such as bubbles, sedimentation or uneven color.

Original Source:https://www.flait-aluminum.com/Anodized-Aluminum-Sheet-Coil.html