- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

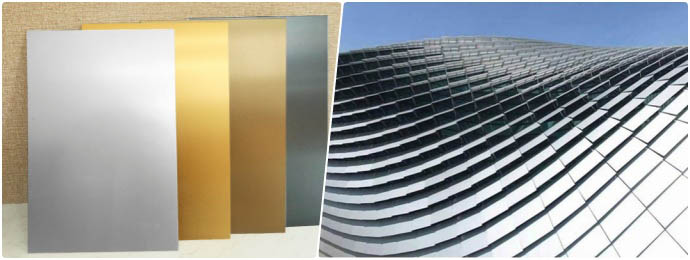

Anodized aluminum veneer panel refers to an aluminum veneer that has been processed by sheet metal after being anodized. After anodizing, the aluminum veneer has significant improvements in wear resistance, corrosion resistance and surface hardness. improvement. It is used for interior decoration and will not discolor, corrode, oxidize or rust for a long time. The anodized aluminum veneer panel with thickened oxide film (10µm) can be used outdoors and will not discolor after long-term exposure to sunlight.

Anodized aluminum veneer panel is a very popular building decoration material. Both designers and construction engineers are shocked by its unique appearance and material properties. It is widely used in indoor ceilings, building facades, indoor and outdoor curtain walls, etc. It not only increases people’s visual enjoyment, but also is easy to care and maintain, has a long service life, is environmentally friendly and fire-resistant.

1. High hardness

1. High hardness

The surface hardness of the anodized aluminum veneer panel is high, reaching gem level, with good scratch resistance and wear resistance.

2. Strong metallic feel

2. Strong metallic feel

The anodized aluminum veneer panel is highly decorative, and the surface is not covered with paint, retaining the metallic color of the aluminum plate and highlighting the modern metallic feel.

3. High fire resistance

3. High fire resistance

Pure metal products, the surface of the anodized aluminum veneer panel is free of paint and any chemical substances, does not burn at 600 degrees high temperature, and does not produce toxic gases, complying with fire protection and environmental protection requirements.

4. Strong stain resistance

4. Strong stain resistance

Easy to clean and maintain, no fingerprints left on the surface, easy to clean, and no corrosion spots.

5. Good processability

5. Good processability

The anodized aluminum veneer panel has moderate hardness and can be easily bent and formed. It can be continuously stamped at high speed and can be directly processed into products. There is no need to go through complicated surface treatment processes, which greatly shortens the product production cycle and reduces product production. cost.

| Alloy series | Alloy | Temper | Thickness(mm) | Width(mm) |

| 1 series | 1060,1070,1100 | HO/H111,H12,H14,H16,H18,H24,H26, etc. | 1.0-4.0 | 100-2650 |

| 3 series | 3003,3004,3005,3105 | HO/H111,H12,H14,H16,H18,H24,etc. | 1.0-4.0 | 100-2650 |

| 5 series | 5005,5052 | HO/H111,H14,H16,H18,H24,H32,H34,etc. | 1.0-4.0 | 100-2650 |

| 6 series | 6061,6063 | T4,T5,T6 | 1.0-4.0 | 100-2650 |

Flait Aluminum is committed to providing customers with one-stop solutions, producing and supplying various grades of deformed aluminum alloy products, providing pre-sales consultation, customized production and free mailing sample services. If you are interested in our products, please contact our team. Click to Order

Original Source:https://www.flait-aluminum.com/Anodized-Aluminum-Sheet-Coil.html