- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

For more detailed information including pricing, customization and shipping.

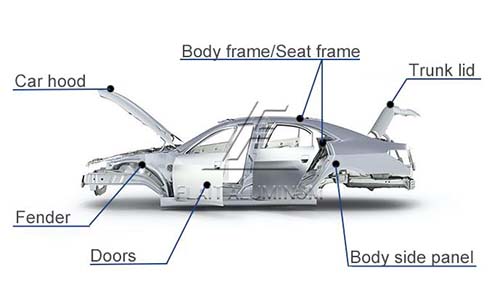

With the demand for environmental protection and energy saving, the lightweight of automobiles has become the development of the global automobile industry. Aluminum as a representative material of automobile lightweight, has become a key raw material for reducing the weight of automobile bodies. Aluminum alloy sheet has the advantages of light weight, high strength, good stretchability, corrosion resistance, etc. The formability and production performance of aluminum sheet are very close to those of steel sheet, so it is very popular in the automobile and auto parts processing industry. Aluminum alloys can also be applied in body, frame, engine, door, cover, fuel tank and compartment body according to the different alloys added, different proportions and different manufacturing processes, which can effectively reduce the overall weight of the vehicle, thereby improving the comprehensive performance.

Commonly used alloys for automotive aluminum sheets are 5*** series and 6*** series. The main aluminum sheets plates for automobiles are:

5182 aluminum sheets plates, 5083 aluminum sheets plates,

5086 aluminum sheets plates, 5754 aluminum sheets plates,

5052 aluminum sheets plates, 5454 aluminum sheets plates,

Temper: O,H14,H24

Temper: O,H14,H24

Temper: O,H32,H34,H26

Temper: O,H111,H32

Temper: O,H111

Temper: O

Temper: O,T4,T451,T6,T651

Temper: O,T4,T5,T6

Temper: O,T4

Aluminum alloys for car body:

|

Alloy |

Temper |

Thickness (mm) |

Width(mm) |

Length (mm) |

Standard |

|

5182 |

O, H111 |

0.50 – 3.50 |

1200 - 2650 |

500 - 16000 |

EN/ASTM |

|

5083 |

H32, H111 |

4.00 – 8.00 |

1500 - 2650 |

2000 - 16000 |

GB/EN/ASTM |

|

5754 |

O |

1.00 – 8.00 |

1200 - 2650 |

500 - 12000 |

GB/EN/ASTM |

|

5052 |

O, H32, H26, H34 |

0.30 – 3.50 |

1200 - 2650 |

500 - 12000 |

GB/EN/ASTM |

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

|

5182 |

0.20 |

0.36 |

0.15 |

0.20-0.50 |

4.00-5.00 |

0.10 |

0.25 |

0.10 |

Remainder |

|

5083 |

0.40 |

0.40 |

0.10 |

0.40-1.00 |

4.00-4.90 |

0.05-0.25 |

0.25 |

0.15 |

Remainder |

|

5754 |

0.40 |

0.40 |

0.10 |

0.50 |

2.60-3.60 |

0.30 |

0.20 |

0.15 |

Remainder |

|

5052 |

0.25 |

0.40 |

0.10 |

0.10 |

2.20-2.80 |

0.15-0.35 |

0.10 |

- |

Remainder |

Aluminum alloys for car body structural parts:

|

Alloy |

Temper |

Thickness(mm) |

Width(mm) |

Length(mm) |

Standard |

|

6061 |

O, T4, T6, T651 |

0.30 – 500 |

100 - 2400 |

500 - 16000 |

GB/EN/ASTM |

|

6063 |

O, T4, T6, T651 |

0.30 – 500 |

100 - 2400 |

500 - 16000 |

GB/EN/ASTM |

|

6082 |

O, T4 |

0.30 – 3.50 |

100 - 2400 |

500 - 16000 |

GB/EN/ASTM |

|

2024 |

O, T4 |

0.50 – 3.50 |

800 - 2400 |

800 - 5500 |

GB/EN/ASTM |

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

|

6061 |

0.40-0.80 |

0.70 |

0.10-0.40 |

0.15 |

0.80-1.20 |

0.04-0.35 |

0.25 |

0.15 |

Remainder |

|

6063 |

0.20-0.60 |

≤0.35 |

≤0.10 |

≤0.10 |

0.40-0.90 |

≤0.10 |

- |

≤0.10 |

Remainder |

|

6082 |

0.70-1.30 |

0.50 |

0.10 |

0.40-1.00 |

0.60-1.20 |

0.25 |

0.20 |

0.10 |

Remainder |

|

2024 |

0.50 |

0.50 |

3.80-4.90 |

0.30-0.90 |

1.20-1.80 |

0.10 |

0.25 |

0.15 |

Remainder |

Aluminum alloys for other car parts:

|

Alloy |

Temper |

Thickness(mm) |

Width(mm) |

Length(mm) |

Standard |

Uses |

|

1050 |

O |

0.30 – 3.50 |

100 - 2400 |

500 - 16000 |

GB/EN/ASTM |

Engine heat shields and parts, water tanks, exhaust pipe heat shield parts, etc. |

|

1060 |

O |

0.30 – 3.50 |

100 - 2400 |

500 - 16000 |

GB/EN/ASTM |

Headlight lampshades, interior panel, etc. |

|

1100 |

O |

0.30 – 3.50 |

100 – 2400 |

500 – 16000 |

GB/EN/ASTM |

Radiator plate, component heat shield, etc. |

|

3003 |

F,O,H12,H14, H16, H18,H22,etc. |

0.20 – 500 |

20 - 2650 |

500 – 16000 |

GB/EN/ASTM |

Energy power battery shell |

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

V |

Zn |

Ti |

Al |

|

|

1050 |

0.25 |

0.40 |

0.05 |

0.05 |

0.05 |

- |

0.07 |

0.05 |

≥99.50% |

|

|

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

0.05 |

0.05 |

0.03 |

≥99.60% |

|

|

1100 |

0.95 |

0.05-0.20 |

0.05 |

- |

- |

0.10 |

- |

Remainder |

||

|

3003 |

0.60 |

0.70 |

0.05-0.20 |

1.00-1.50 |

- |

- |

0.10 |

- |

Remainder |

|

5754 Aluminum sheet plate and 5052 aluminum sheet plate for automobile fuel tanks. The aluminum alloy fuel tank has good corrosion resistance, excellent processability, and light weight. It is very popular for heavy-duty vehicles with high fuel consumption and high requirements on fuel quality.

5754 Aluminum sheet plate and 5052 aluminum sheet plate for automobile fuel tanks. The aluminum alloy fuel tank has good corrosion resistance, excellent processability, and light weight. It is very popular for heavy-duty vehicles with high fuel consumption and high requirements on fuel quality. 5454 Aluminum sheet plate for automobile engines. 5454 aluminum sheet has high strength, high corrosion resistance, good plasticity, and good formability. The strength of 5454 aluminum sheet is about 20% higher than that of 5052 aluminum sheet. 5454 aluminum plate is also widely used in pressure vessels, marine facility pipelines, automobile wheels, and oil tanker barrels.

5454 Aluminum sheet plate for automobile engines. 5454 aluminum sheet has high strength, high corrosion resistance, good plasticity, and good formability. The strength of 5454 aluminum sheet is about 20% higher than that of 5052 aluminum sheet. 5454 aluminum plate is also widely used in pressure vessels, marine facility pipelines, automobile wheels, and oil tanker barrels. 6061 Aluminum sheet plate is used to make the frame and seat frame structure, so that the seat can bear a certain load, provide safe and effective support for the driver and passengers, and can reduce the weight of the car without reducing the capacity of the car, and the center of gravity of the body is reduced. The car is more stable and comfortable to drive.

6061 Aluminum sheet plate is used to make the frame and seat frame structure, so that the seat can bear a certain load, provide safe and effective support for the driver and passengers, and can reduce the weight of the car without reducing the capacity of the car, and the center of gravity of the body is reduced. The car is more stable and comfortable to drive. 5083 Aluminum sheet plate and 5182 aluminum sheet plate for automobile hood. The production process of the outer panel of the hood mainly includes blanking, deep drawing, trimming, flanging, and side flanging. The deep drawing forming is the key process to ensure the quality of the parts. The 5182 aluminum plate has the characteristics of good stamping performance and easy welding and forming .

5083 Aluminum sheet plate and 5182 aluminum sheet plate for automobile hood. The production process of the outer panel of the hood mainly includes blanking, deep drawing, trimming, flanging, and side flanging. The deep drawing forming is the key process to ensure the quality of the parts. The 5182 aluminum plate has the characteristics of good stamping performance and easy welding and forming . 6061 Aluminum sheet plate and 5182 aluminum sheet plate for car doors. The car door is to provide the passage for the driver and passengers to enter and exit the vehicle, and to isolate the interference from the outside of the vehicle, to reduce side impact to a certain extent, and to protect the occupants.

6061 Aluminum sheet plate and 5182 aluminum sheet plate for car doors. The car door is to provide the passage for the driver and passengers to enter and exit the vehicle, and to isolate the interference from the outside of the vehicle, to reduce side impact to a certain extent, and to protect the occupants. 6061 Aluminum sheet plate for front and rear anti-collision beams (bumpers) of automobiles. Automobile bumpers have the functions of safety protection, decoration of vehicles and improvement of aerodynamic characteristics of vehicles.

6061 Aluminum sheet plate for front and rear anti-collision beams (bumpers) of automobiles. Automobile bumpers have the functions of safety protection, decoration of vehicles and improvement of aerodynamic characteristics of vehicles. 5083 Aluminum sheet plate and 5182 aluminum sheet plate for car trunk. The trunk of the car is composed of the rear body frame of the car, the spare tire cover in the middle of the rear body frame and the trunk lid on the top. The trunk lid is an important part of the lightweight of the car as a car opening and closing module.

5083 Aluminum sheet plate and 5182 aluminum sheet plate for car trunk. The trunk of the car is composed of the rear body frame of the car, the spare tire cover in the middle of the rear body frame and the trunk lid on the top. The trunk lid is an important part of the lightweight of the car as a car opening and closing module. 5182 Aluminum sheet plate for the fender of the car. This alloy aluminum plate has a certain cushioning property and is safer. The characteristics of 5182 aluminum alloy meet the requirements of fenders. The aluminum alloy has good corrosion resistance, excellent processing performance and welding performance, stable mechanical properties, better cushioning performance of automobile wheels, and safer driving.

5182 Aluminum sheet plate for the fender of the car. This alloy aluminum plate has a certain cushioning property and is safer. The characteristics of 5182 aluminum alloy meet the requirements of fenders. The aluminum alloy has good corrosion resistance, excellent processing performance and welding performance, stable mechanical properties, better cushioning performance of automobile wheels, and safer driving. 6061 Aluminum sheet plate for automobile wheels. Aluminum alloy automobile wheels reduce the weight of the body and save energy consumption; when the car is running at high speed, due to the friction between the tire and the ground, a lot of heat will be generated. Aluminum alloy wheels can keep the tires at an appropriate temperature and prolong the service life of the tires. Longer service life, reducing the risk of tire blowout; aluminum alloy wheels have better impact resistance, tension resistance and thermal strength and other strength indicators.

6061 Aluminum sheet plate for automobile wheels. Aluminum alloy automobile wheels reduce the weight of the body and save energy consumption; when the car is running at high speed, due to the friction between the tire and the ground, a lot of heat will be generated. Aluminum alloy wheels can keep the tires at an appropriate temperature and prolong the service life of the tires. Longer service life, reducing the risk of tire blowout; aluminum alloy wheels have better impact resistance, tension resistance and thermal strength and other strength indicators. 1050 Aluminum foil and 1060-O aluminum foil is used to make automobile heat shields. The 1060-O aluminum foil is softer. It has the advantages of being poisonous and tasteless, and because of its elegant silver-white luster, it is easy to process beautiful patterns and patterns of various colors, so it is more likely to be favored by people.

1050 Aluminum foil and 1060-O aluminum foil is used to make automobile heat shields. The 1060-O aluminum foil is softer. It has the advantages of being poisonous and tasteless, and because of its elegant silver-white luster, it is easy to process beautiful patterns and patterns of various colors, so it is more likely to be favored by people. 3003 Aluminum coil is used for the battery casing. The 3003 aluminum sheet is an aluminum-manganese alloy with low density and soft material. It has the advantages of good stamping and stretchability, and is easy to stretch and form the aluminum casing of the power battery. The power battery casing made of 3003 aluminum alloy products is impact-resistant, not easy to break and leak, and can meet the strength and rigidity requirements of the power battery casing. Moreover, the low density and light weight of the aluminum alloy can reduce the weight of the battery, increase the capacity density of the battery, make the battery work stably, indirectly reduce the weight of the vehicle, and increase the endurance of the vehicle.

3003 Aluminum coil is used for the battery casing. The 3003 aluminum sheet is an aluminum-manganese alloy with low density and soft material. It has the advantages of good stamping and stretchability, and is easy to stretch and form the aluminum casing of the power battery. The power battery casing made of 3003 aluminum alloy products is impact-resistant, not easy to break and leak, and can meet the strength and rigidity requirements of the power battery casing. Moreover, the low density and light weight of the aluminum alloy can reduce the weight of the battery, increase the capacity density of the battery, make the battery work stably, indirectly reduce the weight of the vehicle, and increase the endurance of the vehicle. 1060 Aluminum coils are used for the soft connection of power batteries. 1060-O aluminum coils have good fusion during loose welding, no burrs, smooth surface, no oxidation, no delamination, firm welding, good electrical conductivity, and fast heat dissipation.

1060 Aluminum coils are used for the soft connection of power batteries. 1060-O aluminum coils have good fusion during loose welding, no burrs, smooth surface, no oxidation, no delamination, firm welding, good electrical conductivity, and fast heat dissipation.