- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

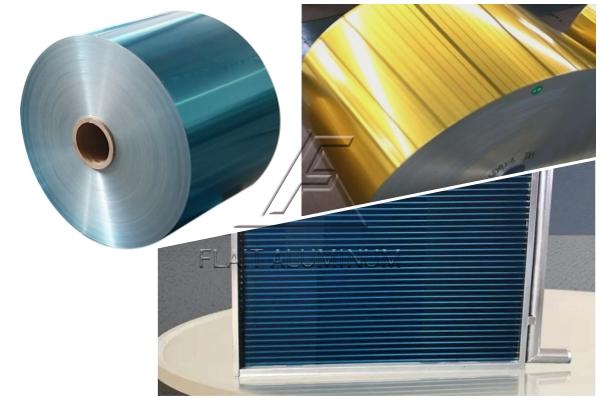

Hydrophilic aluminum fin stock, also known as aluminum foil fins, hydrophilic aluminum foil, are mainly used in the production of heat exchanger fins, such as air-conditioning condensers and evaporators, refrigerator frost-free evaporators/finned evaporators, commercial refrigerator condensers and evaporators, automotive air-conditioning condensers and evaporators, etc. Hydrophilic aluminum foil can be surface-coated, usually blue and gold. Flait Aluminum provides hydrophilic aluminum foil for air conditioner are: 8006, 8011, 3102, 1100, 1030B, etc.

| Alloy | 8011/8006/1100/3102/1030B |

| Temper | O/F,H22,H24,H26,H18 |

| ID | 76MM, 152MM, 300MM, 400MM, 500MM |

| OD | 300 – 1250mm |

| Sleeve Material | Aluminum, carbon, steel |

| Thickness (mm) | 0.08-0.20mm |

| Width (mm) | 100~1250mm |

| Surface | Blue/Golden/ Bare (Pure) |

| Application | Air conditioner condenser, heat exchanger and evaporator etc. |

| Payment | 30% deposit + T/T / L/C at sight |

| Delivery Period | 35~55 days after receiving the deposit |

| Package | Wooden pallets, sea-worthy, with fumigation |

| Standard | EN,ASTM,DIN,GB/T-3198 |

| Shipment Port | Any port in China |

| Chemical composition of blue/golden hydrophilic aluminum fin stock | ||||||||||||

| No. | Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | OTHERS | Al | |

| SINGLE | TOTAL | |||||||||||

| 1 | 1100 | Si+Fe:0.95 | 0.05-0.20 | 0.05 | – | – | 0.1 | – | 0.05 | 0.15 | 99 | |

| 2 | 3102/1030B | 0.2 | 0.3 | 0.1 | 0.3 | 0.05 | 0.05 | 0.1 | 0.08 | 0.2 | Balance | |

| 3 | 8011 | 0.5-0.9 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | 0.08 | 0.05 | 0.15 | Balance |

| 4 | 8006 | 0.4 | 1.2-2.0 | 0.3 | 0.3-1.0 | 0.1 | – | 0.1 | – | 0.05 | 0.15 | Balance |

| Alloy | Temper | Mechanical Performance under room temperature |

| Tensile Strength (σb, Mpa) | ||

| 1100/1200 | O | 60-115 |

| H22 | 90-135 | |

| H24 | 110-160 | |

| H26 | 125-180 | |

| H18 | ≥140 | |

| H19 | ≥150 | |

| 8011 | O | 60-110 |

| H22 | 90-150 | |

| H24 | 120-170 | |

| H26 | 140-190 | |

| H18 | ≥150 | |

| H19 | ≥160 | |

| 3102/1030B | H26 | 125-145 |

| 8006 | O | 90-140 |

| Blue/golden hydrophilic aluminum fin stock coating | ||

| No. | Item Index | Technique Index |

| 1 | Bottom Coating | Epoxy Resin |

| Surface Coating | Acrylic Resin | |

| 2 | Film Thickness | 2.4-2.6µm(Single side average thickness) |

| 3 | Hydrophilic | Primary Contact angle ≤10° |

| Continuous Contact ≤20° | ||

| 4 | Adherence | Erichsen test (Press Depth 5mm): No peeling |

| Gridding test (100/100): No plunger separation | ||

| 5 | Corrosion resistance | Salt spray test (500hours) |

| 6 | Alkali resistance | Dipped in 20% NaOH in 20℃ for 3 minutes, absolutely no blister |

| 7 | Impregnant resistance | Sample’s weight loss≤1% |

| 8 | Heat resistance | Under 200℃ for 5 minutes, performance and color unchanged |

| Under300℃ for 5 minutes, the coating film becomes a little yellow | ||

| 9 | Oil Proof | Dipped in volatile oil for 24 hours, no blister on the coating film |

| 10 | Odor of the coating film | No odor |

| 11 | Abrasion to mould | Same with ordinary aluminum foil |