- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

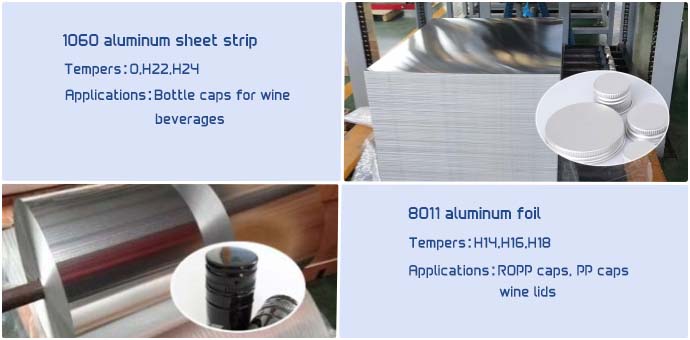

Aluminum bottle caps are increasingly used in people’s lives. Aluminum anti-theft bottle caps are made of high-quality aluminum alloy materials such as 8011 aluminum foil, 1060 aluminum sheet strip, are carefully processed. They are mainly used for alcoholic beverages, beverages (foaming or non-foaming), medical packaging and health products, can meet special requirements such as high-temperature cooking and sterilization. Aluminum bottle caps are usually processed on automated production lines, so the requirements for material strength, elongation and dimensional deviation are very strict, otherwise cracks or creases will appear during processing. In order to ensure that the bottle caps are easy to print after forming, the bottle cap material is required to be flat, without rolling marks, scratches and stains. Commonly used products are 8011 H14 aluminum foil and 1060 H24 aluminum plate, with the thickness of 0.17mm-0.50mm and the width of 449mm-796mm.

1060 aluminum sheet strip is a method of making bottle caps that combines aluminum and plastic. It is industrial pure aluminum with an Al content of at least 99.6%. Its strength is suitable for stamping forming processes. 1060 H24 aluminum sheet has the hardness and formability required for bottle caps. Since the aluminum-plastic bonding part will come into contact with the liquid in the bottle, most of them are used in the cosmetics industry and pharmaceutical industry.

8011 aluminum foil generally adopts the direct stamping method for capping. The main elements of 8011 aluminum foil are Al-Fe-Si, and the rest are trace impurity elements. Its performance is better than pure aluminum foil. 8011 aluminum sheet is not commonly used, but 8011 aluminum foil is widely used, especially in the field of bottle cap materials. 8011 aluminum foil is the main material for PP/ROPP bottle caps. It has good deep drawing performance and low earing rate; it has a certain strength after hardening, which is more in line with the requirements of bottle caps. 8011 aluminum foil is mainly used for white wine caps, red wine caps and PP/ROPP bottle caps, and has the characteristics of good stamping depth and oxidation effect.

The process of 8011 aluminum foil for bottle caps is divided into casting and hot rolling:

◆8011 H18 aluminum bottle cap foil is mainly used for stamping shallow caps and can be cast and rolled.

◆8011 H16 aluminum bottle cap foil is hot-rolled and is mainly used for aluminum anti-theft bottle caps; thickness range 0.15-0.27mm, thickness tolerance ±0.005mm, width range 330-1000mm, width tolerance ±1mm, tensile strength 150-165Mpa, elongation >2%.

8011 H16 aluminum foil is used for medical and wine caps. There are still some subtle differences in the production process, because the tensile requirements of wine bottle caps are higher than those of medicinal bottle caps, so the annealing is also different.

| Bottle cap material | 1060 aluminum sheet strip | 8011 aluminum foil |

| Tempers | O,H22,H24,H16,H18 | |

| Thickness (mm) | 0.15-0.50 | |

| Width (mm) | 500-2500 | |

| Length (mm) | According to customer’s requirement | |

| Rolling process | CC/DC | |

| Delivery time | 25-30 days | |

| Sample | Available | |

| Alloys | Tempers | Thickness (mm) | Tensile strength (Rm/Mpa) | Elongation(%) | Earing rate(%) |

| 1060 | H22 | 0.4-0.5 | 75-110 | 6 | 5 |

| 1060 | O | 0.15-0.5 | 55-95 | 15 | 6 |

| 8011 | H14 | 0.15-0.5 | 125-165 | 2 | 3 |

| 8011 | H16 | 0.15-0.5 | 130-165 | 1 | 3 |

| 8011 | H18 | 0.2-0.5 | ≥165 | 1 | 3 |

Original Source:https://www.flait-aluminum.com/Aluminum-Sheet-Coil-for-Cap-Closure.html