- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

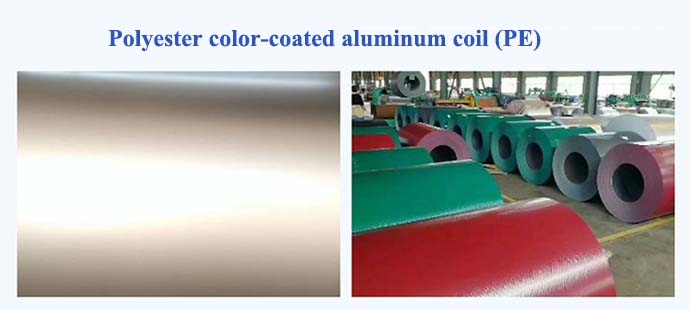

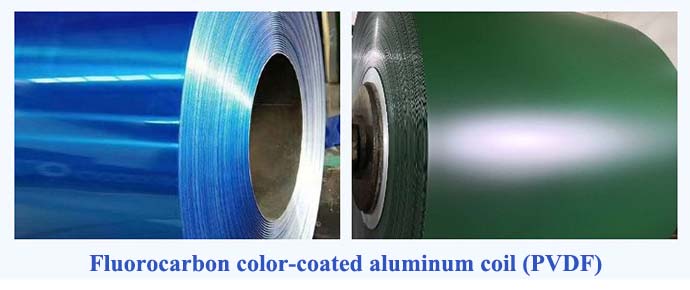

Color-coated aluminum coil refers to the depiction and coloring of aluminum substrate floor. Common types include polyester color-coated aluminum coil (PE) and fluorocarbon color-coated aluminum coil (PVDF), which are widely used in aluminum-plastic panels, industrial manufacturing unit roof walls, aluminum blinds, composite panels, aluminum ceilings, cans and digital products. Its overall performance is very stable and no longer easily corroded, making it a new type of material.

Polyester color-coated aluminum coil (PE) is an anti-ultraviolet coating, polyester resin with a polymer containing an ester bond in the main chain as a monomer, and alkyd resin is added. UV absorbers can be divided into matte and over-gloss mainly according to gloss. It can give colorful aluminum products rich colors, ideal gloss and smoothness, reliable texture and feel, and can further expand the experience of layering and three-dimensional sense. Polyester color-coated aluminum coil (PE) can prevent objects from being exposed to the environment and attacked by ultraviolet radiation, wind, rain, frost and snow; the coating can provide protection due to temperature differences, freeze-thaw cycles, corrosive gases and microbial effects. Polyester color-coated aluminum coil (PE) is particularly suitable for interior decoration.

Fluorocarbon color-coated aluminum coil refers to PVDF resin, which generally refers to coatings made of homopolymers of vinylidene fluoride or copolymers of vinylidene fluoride and different small amounts of fluorinated vinyl monomers. The chemical form based on fluorine acid is combined with the help of fluorine/carbonization. The stability and firmness of this chemical form make the body residence of fluorocarbon coatings different from ordinary coatings. In addition to having good wear resistance in mechanical properties, it also has high-quality weather resistance, long-term anti-fading and UV resistance, especially in harsh climates and environments. Fluorocarbon color-coated aluminum coil (PVDF) is particularly suitable for indoor and outdoor decoration in public places, etc.

◆ Alloy: 1100, 1050, 1060, 1070, 3003, 3004, 3105, 5052, 5005, etc.

◆ Width: ≤ 2000mm.

◆ Length: According to requirements.

◆ Thickness: 0.20mm-6.00mm, coating thickness 5-25UM.

◆ Surface: Single color aluminum plate, aluminum with coating on both sides, mirror finish aluminum coil, stone and marble coated aluminum coil, powder coated aluminum with wood finish, printed and brushed coated aluminum. Coated aluminum, coated aluminum coil sheet with stucco embossed finish, etc.

◆ Overall dimensions: 1.0*1219*2438mm, 2.0*1220*2440mm, 3.0*1200*2400mm, 3.0*1500*3000mm, 2.5*1250*2500mm, etc.

◆ Standards: ASTM-B-209M, BS EN 485-2, BS EN 573-3, GB/T3880-2008

1. Flatness:

1. Flatness:There is no composite high temperature indentation on the surface. The board floor has no residual stress and will not deform after shearing.

2. Decorativeness:

2. Decorativeness:It is coated with wood and stone patterns, with obvious body texture and active beauty. The samples are made at will, providing customers with a wide range of personalized choices, which can enrich the humanistic connotation of the product and provide additional aesthetic enjoyment for humans.

3. Weather resistance:

3. Weather resistance:The coating samples made by coating and high temperature baking have excessive gloss retention, correct coloring stability and very small coloring difference changes. The warranty period of polyester paint is 10 years, while the warranty period of fluorocarbon paint is more than 20 years.

4. Mechanical:

4. Mechanical:Select very good aluminum, plastic and adhesive, and bear superior composite technology.

5. Environmental protection:

5. Environmental protection:Resistant to salt, alkali and acid rain corrosion, it will not corrode and produce toxic bacteria, does not release any toxic gases, does not cause rust on the keel and fixings, and is flame retardant. According to national regulations, it is not less than B1 grade.