- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

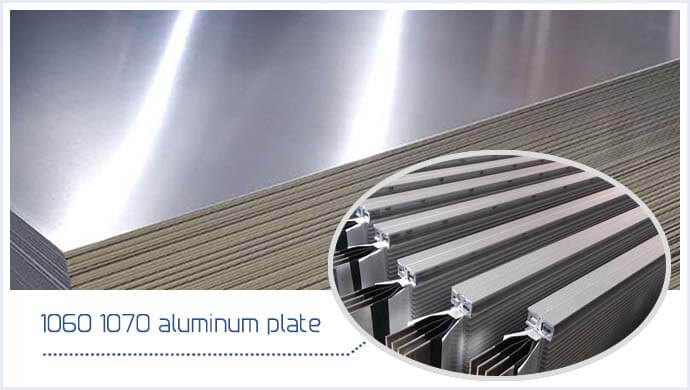

Closed bus duct (referred to as bus duct) is a busbar system composed of metal plates (steel plates or aluminum plates) as protective shells, conductive bars, insulating materials and related accessories. The main features of aluminum plates for aluminum alloy bus ducts are corrosion resistance, light weight and high strength. Aluminum alloy bus ducts are mostly processed and produced with pure aluminum plates. The main alloy grades are 1060 aluminum plates and 1070 aluminum plates, and the common thickness ranges from 10-400mm. The common sizes of conductive aluminum bars 1060 are: 80 x 10mm, 70 x 3mm.

1060 busbar aluminum plates have high electrical conductivity, good thermal conductivity and high corrosion resistance. It is relatively easy to weld, and can be gas welded, hydrogen atom welded and contact welded, but brazing is not easy. 1060 aluminum plates have good ductility and tensile strength, and can meet the requirements of stretching and stamping in conventional production.

Excellent conductivity

Excellent conductivity1060 aluminum plate has excellent conductivity, and its conductivity is as high as 60% or more, which can effectively reduce the resistance of the bus duct and reduce the loss during power transmission.

Good corrosion resistance

Good corrosion resistance1060 aluminum plate has good corrosion resistance after special treatment, which can effectively prevent the corrosion of the bus duct in a humid environment and extend the service life of the bus duct.

Light weight

Light weight1060 aluminum plate has a lighter weight than other metal materials, making the bus duct more convenient during installation, transportation and later maintenance.

High strength

High strength1060 aluminum plate has good mechanical properties, and its tensile strength and hardness are both high, which can meet the use requirements of the bus duct in a high-voltage environment.

Easy to process

Easy to process1060 aluminum plate has good processing performance and can be cut, bent, drilled and other operations, which is convenient for the production and processing of bus duct

1060 aluminum plate can be used to manufacture the conductive busbar and shell of the bus duct. The conductive busbar is the main component for current transmission in the bus duct and needs to have excellent conductivity and corrosion resistance. The shell plays a role in protecting and supporting the conductive busbar and needs to have high strength and good mechanical properties. The advantages of 1060 aluminum plate in these aspects make it the preferred material for bus duct manufacturing.

| Alloys | Tempers | Thickness (mm) | Width (mm) | Length (mm) | Uses |

| 1060 Aluminum plate | F,O, H111, H112 | 10-400 | 100-2500 | 400-15000 | Aluminum busbar,battery soft connector,radiator,charging pile, positive and negative horizontal aluminum busbar,negative upper aluminum busbar, etc. |

| 1070 Aluminum plate | |||||

| Standards | National standard, American standard, European standard, Russian standard, Japanese standard, etc. | ||||

1060 aluminum plate price = Shanghai SMM aluminum ingot price + 1060 aluminum plate processing cost

Because the aluminum busbar has different specifications, its quotation will also be different. For specific quotations, please consult our aluminum experts.