- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

6061 aluminum plate is widely favored by consumers for its good mechanical properties, processability, weldability and corrosion resistance, and these properties are due to its multiple states or heat treatments to choose from. The main states of 6061 aluminum plate include F, O, T4, T6, T651, etc., among which 6061 T6 and 6061 T651 are the two most commonly used states. This article will explain the differences between the two.

6061 T6 and 6061 T651 are two heat treatment states, among which:

T6 state:6061 aluminum alloy undergoes artificial aging after solution heat treatment. During solution treatment, aluminum alloys are heated to high temperatures and then rapidly cooled to increase hardness. Next, it is heated again to a lower temperature and aged to further enhance the material’s properties. Aluminum alloy in T6 state has good strength and corrosion resistance.

T651 state:6061 aluminum alloy is stretched and balanced based on the T6 state. This process is called Stretching Balance Treatment. Its purpose is to make the internal stress distribution of the aluminum alloy more uniform by adjusting it. Therefore, aluminum alloy in T651 state has better mechanical properties and resistance to deformation.

Aluminum plates 6061 T6 and 6061 T651 have the same alloy composition, Thermal Properties and Electrical Properties. Their difference lies in their different mechanical properties.

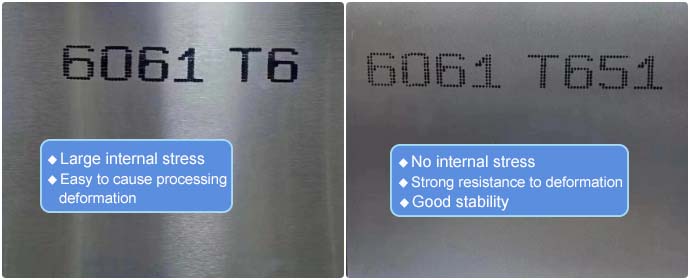

The internal stress of the 6061 T6 aluminum plate will be relatively large, which may cause processing deformation; while the 6061 T651 aluminum plate is based on T6 Stretching eliminates internal stress.

6061 T651 aluminum plate has higher resistance to deformation and better stability than 6061 T6 aluminum plate.

| Alloy-Temper | 6061 T6 | 6061 T651 |

| Elongation at Break, % | 10 | 9 |

| Fatigue Strength, MPa | 96 | 100 |

| Shear Strength, MPa | 210 | 170 |

| Tensile Strength: Ultimate (UTS), MPa | 310 | 290 |

| Tensile Strength: Yield (Proof), MPa | 270 | 270 |

Tags:6061 aluminum plate