- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

Modern heat sink technology is developing rapidly, and the choice of materials is crucial for heat sink efficiency and service life. Aluminum alloy is light in weight, simple to manufacture and low in cost, making it an ideal choice for most heat sinks.

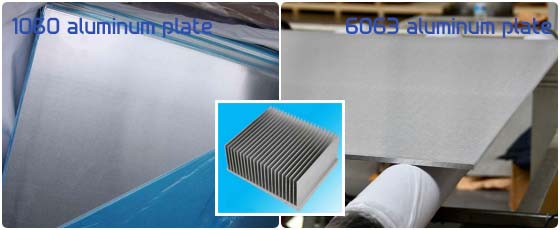

In the manufacture of heat sinks, 1060 aluminum plate and 6063 aluminum plate are commonly used materials, especially in the application of aluminum skived fin heat sinks. These two aluminum alloys each have their own unique properties and advantages, suitable for different heat sink needs.

1060 aluminum plate is industrial pure aluminum with high plasticity, corrosion resistance, electrical conductivity and thermal conductivity. This material has unique advantages in the production of skived fin heat sinks. First, 1060 aluminum plate is easy to process, and various shapes of heat sink fins can be made through precise planer cutting and CNC processing technology. Secondly, 1060 aluminum plate has excellent thermal conductivity and can quickly transfer heat to the surface of the heat sink, thereby achieving efficient heat dissipation. However, the strength of 1060 aluminum plate is low, and other strengthening measures may be required for heat sinks that need to withstand greater pressure or impact.

Performance characteristics

Performance characteristics◆ Thermal conductivity: 1060 aluminum plate has extremely high thermal conductivity and can effectively dissipate heat, making it suitable for heat dissipation of high-heat electronic components.

◆ Purity: The aluminum content of 1060 aluminum plate is as high as 99.6%, so it has good corrosion resistance and processing performance.

◆ Mechanical strength: Although its strength is not as good as 6063 aluminum plate , it is still sufficient in many heat dissipation applications.

6063 aluminum plate belongs to aluminum-magnesium-silicon alloy, which has high hardness and excellent processing performance. This material has also been widely used in the production of skived radiators. 6063 aluminum sheet has high hardness and can withstand greater pressure and impact, so it has obvious advantages in making radiators with high density, large tooth height or pitch ratio. At the same time, 6063 aluminum sheet also has good thermal conductivity and can achieve efficient heat dissipation. In addition, 6063 aluminum sheet also has good corrosion resistance and can maintain stable performance in harsh environments.

Performance characteristics

Performance characteristics◆ High strength: 6063 aluminum plate has high mechanical strength, suitable for withstanding greater physical pressure, and suitable for radiator design requiring higher structural strength.

◆ Good processability: 6063 aluminum plate is easy to process and form, suitable for radiator design with complex shapes, such as skived-tooth and insert-type radiators.

◆ Surface treatment: 6063 aluminum plate has good surface treatment performance, suitable for surface treatment processes such as anodizing, and enhances corrosion resistance and aesthetics.

When choosing between 1060 and 6063 aluminum alloy as the heat sink material, the following factors can be considered:

◎Thermal conductivity requirements: If the heat sink mainly focuses on thermal conductivity, 1060 aluminum alloy may be a better choice.

◎Structural strength: For heat sinks that need to withstand higher pressure or complex shapes, 6063 aluminum alloy is more suitable.

◎Processing and surface treatment: 6063 aluminum alloy performs well in processing and surface treatment, suitable for diverse design requirements.