- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

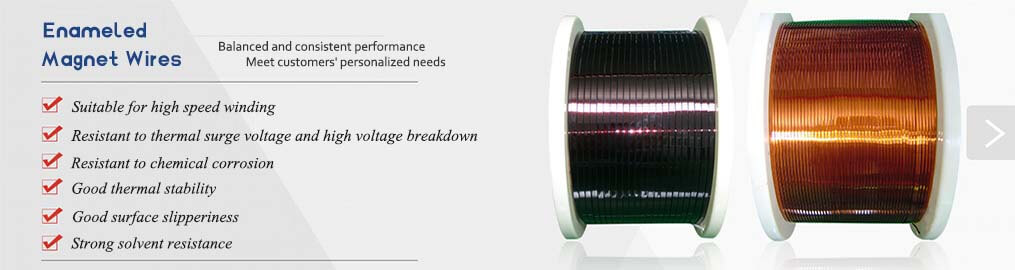

Enameled wire is a type of magnetic wire. Magnetic wire is also known as winding wire, is an insulated wire used to make coils or windings in electrical products. It is a wire that converts electrical energy and magnetic energy into each other. As long as it is in contact with electricity, many machines need to use magnetic wire, and magnetic wire is divided into four categories: enameled wire, winding wire, inorganic insulated wire, and special magnetic wire due to factors such as the use and use environment, etc.

1. Enameled wire is the most contacted and used electromagnetic wire among us. The most common enameled wire we have is polyesterimide enameled wire.

1. Enameled wire is the most contacted and used electromagnetic wire among us. The most common enameled wire we have is polyesterimide enameled wire. 2. Winding wire, magnetic wire is generally wrapped with insulating paper, glass fiber and other insulating materials on bare wire or enameled wire. Common ones on the market include silk-covered wire, glass fiber-covered wire, paper-covered wire, etc.

2. Winding wire, magnetic wire is generally wrapped with insulating paper, glass fiber and other insulating materials on bare wire or enameled wire. Common ones on the market include silk-covered wire, glass fiber-covered wire, paper-covered wire, etc. 3. Inorganic insulated wire, the material selected for the insulation layer is ceramic, glass film and other materials.

3. Inorganic insulated wire, the material selected for the insulation layer is ceramic, glass film and other materials. 4. Special magnetic wire, electromagnetic wire selected according to special occasions, such as high-frequency winding wire, submersible motor winding and other special uses.

4. Special magnetic wire, electromagnetic wire selected according to special occasions, such as high-frequency winding wire, submersible motor winding and other special uses.

The thermal class of ordinary polyester enameled wire is 130, and the thermal class of modified enameled wire is 155. This product has high mechanical strength and good elasticity, adhesion, electrical properties and solvent resistance. Its weaknesses are poor heat shock resistance and low moisture resistance. Polyester enameled wire is widely used, mainly in various motors, electrical appliances, instruments, telecommunications equipment and home appliances.

2. Polyurethane enameled wire

2. Polyurethane enameled wireThe thermal classes of polyurethane enameled wire are 130, 155, 180 and 200. It has direct solderability, good high-frequency resistance, easy coloring and good moisture resistance. It is widely used in electronic appliances, precision instruments, telecommunications and instruments.

Polyesterimide/polyamide composite enameled wire with thermal class 180 has good heat shock resistance, high softening breakdown temperature, excellent mechanical strength, good solvent resistance and refrigerant resistance. Its weakness is that it is easy to hydrolyze under closed conditions. It is widely used in windings of motors, electrical appliances, instruments, power tools, dry-type power transformers, etc. with high heat resistance requirements.

It is a widely used heat-resistant enameled wire with a thermal class of 200. The product has high heat resistance and also has the characteristics of refrigerant resistance, severe cold resistance, radiation resistance, etc. It has high mechanical strength, stable electrical properties, good chemical resistance and refrigerant resistance, and strong overload capacity. It is widely used in refrigerator compressors, air-conditioning compressors, power tools, explosion-proof motors, and motors and electrical appliances used under high temperature, severe cold, radiation resistance, overload and other conditions.

1. Material preparation

1. Material preparationThe raw materials of electromagnetic wire are transported to the production site by carts. The preparation of insulating paint is completed in the paint configuration room. According to the different insulation levels of various electromagnetic wires, a certain proportion of paint and thinner are fully mixed and evenly added to the enameling machine.

2. Wire drawing

2. Wire drawingWire drawing is carried out in the wire drawing machine, and is drawn once or multiple times according to the required wire diameter. The temperature during drawing can generally reach 60-100℃, and water-soluble lubricants are used for lubrication and cooling. When the temperature exceeds 100℃, supplementary cooling and heat removal are carried out.

3. Water washing

3. Water washingWater washing is to use water purified by hydrochloric acid and caustic soda to wash the electromagnetic wire with high-pressure water flow to remove oil stains on its surface.

4. Annealing

4. AnnealingAnnealing is generally carried out in an annealing furnace by electric heating. The annealing temperature is generally controlled at 300-600℃. During annealing, water vapor is used for protection to prevent oxidation. After annealing, a hair dryer is used for air cooling, and it enters the impregnation section at about 40℃.

5. Impregnation

5. ImpregnationThe impregnation process is carried out in the enameling machine and is completed multiple times according to the requirements of the insulation layer. During the impregnation, a proper proportion of diluent is added according to the needs of the coating. The diluent contains flammable and toxic liquids such as cresol and xylene.

6. Drying

6. DryingThe drying of the electromagnetic wire is carried out in a drying furnace. The drying temperature is determined according to the speed of wire drawing, generally 300-400℃. It can reach up to 670 degrees Celsius. Drying and exhaust gas removal are carried out simultaneously. The exhaust gas (temperature is 300-400 degrees Celsius) contains toxic and flammable vapors such as cresol, phenol, and xylene. After the catalytic reaction reaches the environmental protection index, it is discharged into the atmosphere by the exhaust fan.

7. Reeling

7. ReelingReeling is to use the reeling device to wind the dried electromagnetic wire product on the reel. A small amount of lubricant (974 gasoline, cyclohexane) needs to be added when reeling.

8. Packaging and warehousing

8. Packaging and warehousingAfter passing the inspection, the wound wire reels are wrapped with plastic film and placed in cartons or paper tubes. They are packaged into wire drags according to user needs and loaded and unloaded into a dedicated warehouse.

Original Source:Magnet Wires for Power Industry