- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

For more detailed information including pricing, customization and shipping.

Flait Aluminum is committed to the research, development and production of various specifications of magnet wires. The conductive wire products provided are formed by high-temperature extrusion process, and the forming heat treatment is integrated. They have stable low resistance and low resistivity, good surface finish, good flexibility, mechanical toughness and conductivity are greatly improved compared with aluminum wire products produced by traditional drawing process.

The main products include 120, 130, 155, 180, 200, 220 class enameled copper (aluminum) rectangular wire, enameled round wire, NOMEX paper covered copper (aluminum) rectangular wire, polyester enameled copper (aluminum) rectangular wire, polyester-imide enameled copper (aluminum) rectangular wire, paper-wrapped copper (aluminum) wire, bare copper (aluminum) and other magnetic wires. The products are used in transformers, reactors, motors, new energy and other power systems.

Standards: GB/T 6109.4, GB/T6109.10, GB/T6109.23, JIS-C3202, IEC60317-19, IEC60317-21, etc.

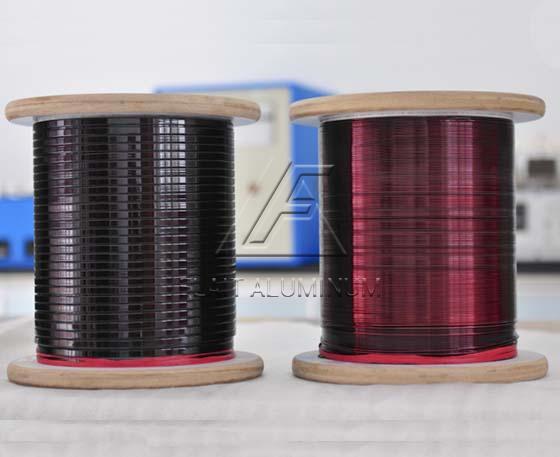

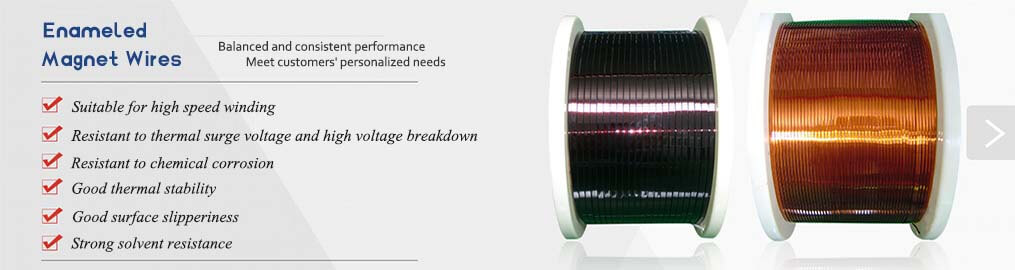

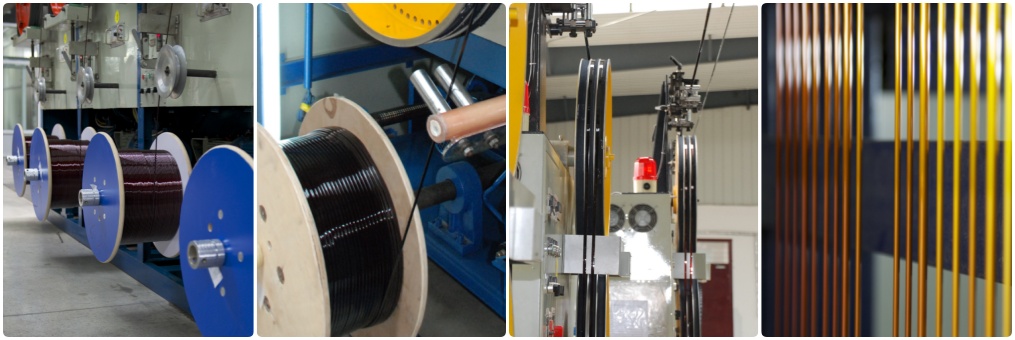

● Enameled Magnet Wires

Enameled wire is a wire made by coating one or more layers of insulating varnish on the surface of a metal conductor and then baking it. It consists of a conductor (usually copper or aluminum) and an insulating layer (paint film). The paint film is usually formed by applying insulating varnish and then drying it. The insulating properties of enameled wire enable it to effectively realize the conversion of electromagnetic energy in electrical equipment, and it is often used in oil-immersed transformers, dry-type transformers, reactors, motors, chokes, air compressors, home appliances and other products. Click to Order

Enameled wire is mostly provided in the form of round wire or flat wire. According to the insulation material and temperature resistance grade, it can be divided into polyester enameled wire (temperature resistance grade of 130℃), polyesterimide enameled wire (temperature resistance grade of 180℃), polyurethane enameled wire (temperature resistance grade of 130-155℃), polyamideimide enameled wire (temperature resistance grade of 200-220℃), acetal enameled wire (temperature resistance grade of 105-120℃), etc.

● Paper Covered Magnet Wires

Paper covered magnet wire is made by wrapping Nomex paper, cable paper, polyester non-woven fabric, polyimide film evenly around high-quality copper (aluminum) conductors, so that the film and the conductor are bonded into a whole. This product has excellent voltage resistance and thin insulation thickness, and heat resistance up to 220℃. Paper covered magnet wire is mainly used in high-voltage power cables, control cables and signal cables as insulation materials, especially in electromagnetic wire factories, transformer factories, mutual inductor factories, reactor factories and other fields. Click to Order

Thermal class: 130, 155, 180, 200

Material: Aluminum,Copper

Material: Aluminum,Copper

Material: Aluminum,Copper

Thermal class: 130, 155

Material: Aluminum,Copper

● Fiberglass Insulated Wires

Glass-fiber wound wire is formed by covering the work piece such as aluminum wire or copper wire with insulating paint, then wrapping it with glass fiber, and drying it. Glass fiber covered wire is evenly wrapped with 1 to 2 layers of alkali-free glass fiber on the copper (aluminum) conductor. It needs to be impregnated and baked with insulating paint with heat resistance index and compatibility, so that the glass fibers and the glass fibers and the conductor are bonded into a whole. The heat resistance index of this type of product has three classes: 130, 155, and 180, the insulation thickness usually has four levels: 20, 30, 40, and 50.

The insulation layer of glass-fiber wound wire has certain wear resistance, adhesion and softness, and has good resistance to thermal shock and overload. Glass fiber covered wire products are widely used in the windings of transformers, electromagnets, welding machines or other electrical equipment products. Click to Order

Thermal class: 130, 155, 180, 200

Material: Aluminum,Copper

Thermal class: 130, 155, 180, 200

Material: Aluminum,Copper

Thermal class: 130, 155, 180

Material: Aluminum,Copper

Thermal class: 130, 155, 180, 200

Material: Aluminum,Copper

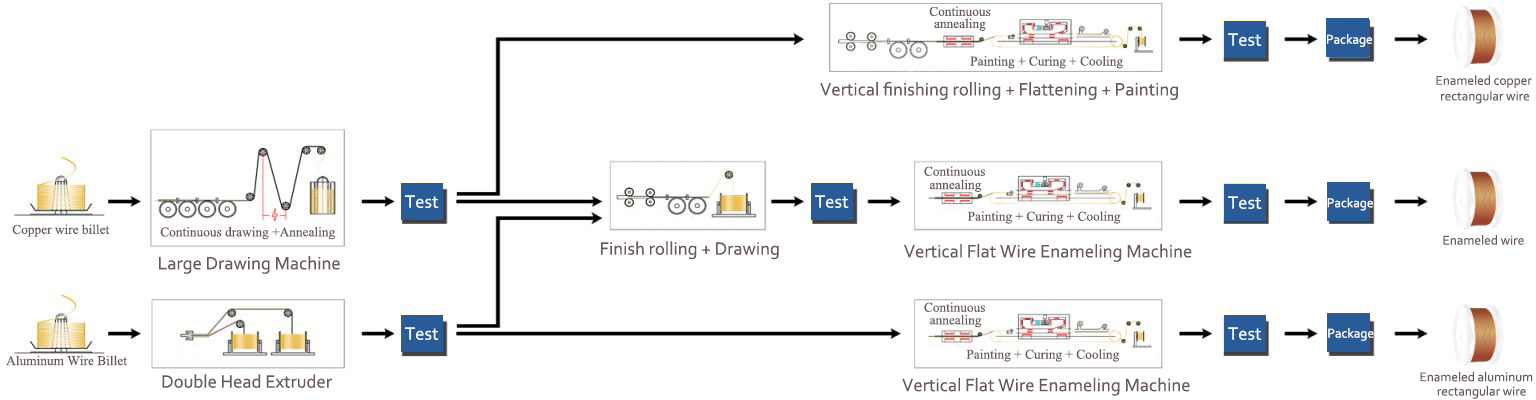

Enameled Magnet Wire Production Process

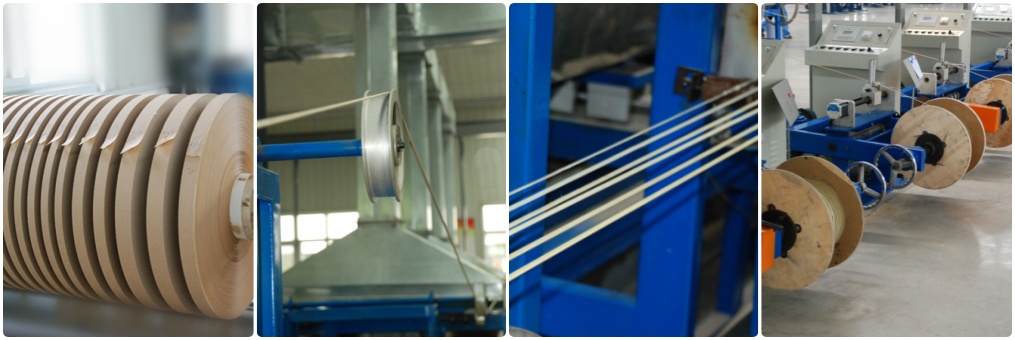

Paper covered wire production process

Transformers

Transformers Electromagnetic generators windings

Electromagnetic generators windings Electromagnetic coil

Electromagnetic coil Motor windings

Motor windings Inductors

Inductors Communication device

Communication device New energy vehicle

New energy vehicle