- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

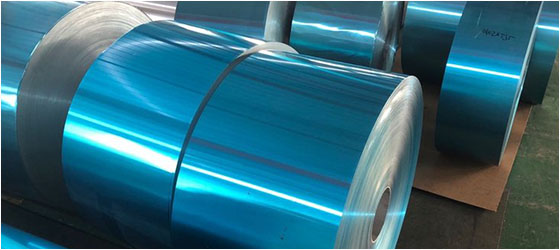

Air conditioner aluminum foil including bare aluminum foil, blue and gold hydrophilic aluminum foil, which also called aluminum fin stock foil. Air conditioner aluminum foil is mainly used in the production of heat exchanger fins, such as condensers and evaporators of air conditioner, refrigerator, automotive, etc. Coated aluminum foil (hydrophilic aluminum foil) is formed on the basis of bare aluminum foil (uncoated aluminum foil) after surface coating treatment. In addition to the chemical composition, mechanical properties and geometric dimensions of uncoated aluminum foil, hydrophilic aluminum foil also has good plate shape and coating properties. The main coated aluminum foils for air conditioning are: 8006 hydrophilic aluminum foil, 8011 hydrophilic aluminum foil, 3102 hydrophilic aluminum foil, 1100 hydrophilic aluminum foil, etc.Click to Order

| Alloy | 8011/8006/1100/3102/1030 |

| Temper | O/F,H22,H24,H26,H18 |

| ID | 76MM, 152MM, 300MM, 400MM, 500MM |

| OD | 300 – 1250mm |

| Sleeve Material | Aluminum, carbon, steel |

| Thickness (mm) | 0.08-0.20mm |

| Width (mm) | 100~1250mm |

| Surface | Blue/Golden/ Bare (Pure) |

| Application | Air conditioner condenser, heat exchanger and evaporator etc. |

| Payment | 30% deposit + T/T / L/C at sight |

| Delivery Period | 35~55 days after receiving the deposit |

| Package | Wooden pallets, sea-worthy, with fumigation |

| Standard | EN,ASTM,DIN,GB/T-3198 |

| Shipment Port | Any port in China |

| Performance of hydrophilic coating aluminum foil for air conditioner | ||

| No. | Item Index | Technique Index |

| 1 | Bottom Coating | Epoxy Resin |

| Surface Coating | Acrylic Resin | |

| 2 | Film Thickness | 2.4-2.6µm(Single side average thickness) |

| 3 | Hydrophilic | Primary Contact angle ≤10° |

| Continuous Contact ≤20° | ||

| 4 | Adherence | Erichsen test (Press Depth 5mm): No peeling |

| Gridding test (100/100): No plunger separation | ||

| 5 | Corrosion resistance | Salt spray test (500hours) |

| 6 | Alkali resistance | Dipped in 20% NaOH in 20℃ for 3 minutes, absolutely no blister |

| 7 | Impregnant resistance | Sample’s weight loss≤1% |

| 8 | Heat resistance | Under 200℃ for 5 minutes, performance and color unchanged |

| Under300℃ for 5 minutes, the coating film becomes a little yellow | ||

| 9 | Oil Proof | Dipped in volatile oil for 24 hours, no blister on the coating film |

| 10 | Odor of the coating film | No odor |

| 11 | Abrasion to mould | Same with ordinary aluminum foil |

1. Aluminum foil plate shape:

First, the production process of hydrophilic coating aluminum foil (coated aluminum foil) requires the aluminum foil to have a good plate shape, which is a prerequisite for the production of coated aluminum foil. The unit for measuring plate shape indicators is I. Generally, the plate shape requirements of coating production equipment are within 20-40I. If it is greater than this value, a tension straightening system needs to be added in front of the coating equipment. Generally, the aluminum strip running routes of coating equipment are long, and there are many processing procedures and guide rollers. Therefore, if the tension straightening system is not equipped, once the plate shape is not good, it will easily break during operation, resulting in the failure of production. The air-conditioning production process also has high requirements on the shape of aluminum foil. General heat exchanger fin punching production lines use vacuum suction cups to transport aluminum foil. If the shape of the aluminum foil is not good and the surface is uneven, the vacuum suction transport of the aluminum foil will not work properly. Therefore, the plate shape is not only an important technical indicator of coated aluminum foil, but also uncoated aluminum foil.

2. Coating performance:

The coated aluminum foil currently used on the market is mainly hydrophilic aluminum foil. Hydrophilic aluminum foil is a hydrophilic treatment of aluminum foil. Through a special process, a hydrophilic layer is coated on the surface. The condensed water will condense on the hydrophilic aluminum foil. It spreads quickly without condensing into water droplets, increases the heat exchange area, speeds up cooling and heating, and effectively avoids noise caused by condensed water blocking the air flow.

3. Coating thickness:

There is no strict rule for the thickness of the coating film on the surface of aluminum foil, but it is generally less than 3/1m. Since coatings are generally more expensive, control the thickness of the coating while meeting performance requirements can reduce production costs. The coating thickness directly affects various performance indicators of the coating, so the coating thickness on the surface of the aluminum foil is required to be uniform.

4. Coating adhesion:

Coating adhesion is an indicator of how fast the aluminum foil adheres to its surface coating. If the coating adhesion is too small, the surface coating of the coated aluminum foil will easily fall off during further processing and use, which will seriously affect the weight of the coated aluminum foil. Therefore, the stronger the coating adhesion, the better. Coating adhesion can generally only be tested qualitatively. The main testing methods include friction resistance test, cross-hatch test and cupping method.

5. Hydrophilic properties:

After a period of use of hydrophilic aluminum foil, the hydrophilic properties of the surface will be affected by various environmental factors. Therefore, hydrophilic properties are generally divided into initial hydrophilic properties and hydrophilic properties after environmental resistance tests. The quality of hydrophilic properties is mainly measured by the size of the A angle. Generally, the initial hydrophilicity requirement of a product is a<100, and the hydrophilicity requirement after environmental resistance test is a<250. The contact angle “a” can be measured with a special contact angle measuring instrument; it can also be calculated by the area occupied by a certain volume of water droplets on the surface of the aluminum foil.

6. Corrosion resistance:

Corrosion resistance is mainly reflected in three aspects: First, alkali resistance. Since the lubricating oil on the surface of the heat exchange fin needs to be removed with an alkaline cleaning agent after being punched, the functional coating on the surface of the aluminum foil must have a certain degree of alkali resistance, it is generally required to be immersed in 20% NaOH solution for 3 minutes without bubbling; Second, salt spray corrosion resistance, generally it is required that there should be no corrosion spots for 500 hours in a 35°C, 3% salt water spray environment. The resistance to salt spray corrosion is directly related to the service life of the heat exchanger. In coastal areas, due to the high salt content in the air, there are higher requirements for the salt spray corrosion resistance of the heat exchanger; Third, heat and humidity resistance, that is, corrosion resistance when placed under a certain temperature and humidity for a long time. This performance is also an important indicator of the weather resistance of the heat exchanger.

Original Source:https://www.flait-aluminum.com/Hydrophilic-Aluminum-Foil-For-Air-Conditioner-Heat-Exchanger.html

Tags:air conditioner aluminum foil,hydrophilic aluminum foil