- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

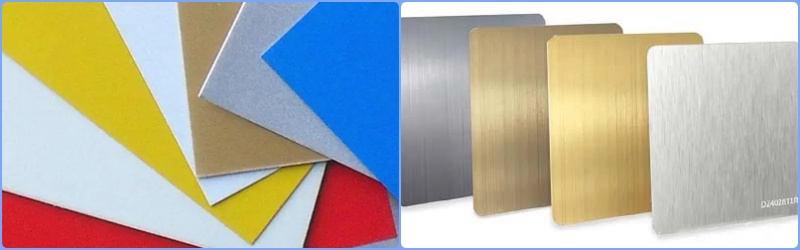

Anodized aluminum sheet and painted aluminum sheet are two common aluminum sheet deep processing products. The two use different metal surface treatment processes, so there are different differences. This article explores the differences between the two.

1.Different processes

1.Different processesAnodized aluminum sheet is a material protection technology in which an aluminum sheet is placed in an electrolyte solution and an anodic current is applied to form an oxide film on its surface, also known as surface anodization.

Painted aluminum sheet, also known as pre-painted aluminum sheet, is made by spraying various colors of paint on the surface of the aluminum sheet and then curing it at high temperature. According to the different materials, it can be divided into PE sprayed aluminum sheet and PVDF sprayed aluminum sheet.

2.Weather resistance

2.Weather resistanceThe weather resistance of anodized aluminum sheet and painted aluminum sheet is not much different. Both can withstand sunlight for a long time without discoloration and can be used in outdoor environments for a long time.

3.Corrosion resistance

3.Corrosion resistanceWhen both the oxide film and the paint film meet the standards, they can withstand the test of high temperature, low temperature and acid rain, and will not fall off. But relatively speaking, the corrosion resistance of anodized aluminum sheet is better.

4.Color selection

4.Color selectionIn terms of color selection, paint aluminum plates are richer than anodized aluminum plates. Anodized aluminum plates have a metallic texture that paint aluminum plates do not have, but the colors are relatively few. Although paint aluminum plates lack metallic texture, they have rich colors, not only pure colors, but also more complex colors, such as wood grain and stone grain.

5.Surface quality

5.Surface qualityThe surface quality of anodized aluminum plates is better than that of paint aluminum plates. Whether it is smoothness, flatness or surface hardness, it is better than paint aluminum plates. This is mainly due to the different processing techniques of the two. The oxide film formed by anodizing treatment is more dense.

6.Processing performance

6.Processing performanceAnodized aluminum plates can be bent, and the processability is much better than that of paint aluminum plates. Anodized films are less likely to crack than paint coatings.

7.Application Scope

7.Application ScopeBoth anodized aluminum plates and painted aluminum plates can be used in the field of architectural decoration, such as building exterior walls, interior decoration, etc. However, the focus of the two application fields is different. Anodized aluminum plates are mainly suitable for scenes with high requirements for surface quality and durability, such as outdoor applications, industrial machinery and 3C product shells; painted aluminum plates are mainly used in indoor scenes to prevent daily minor scratches and wear. Due to the wide range of color choices, they are more commonly used in furniture, decorative building materials, roofing systems, etc.

8.Price

8.PriceThe anodizing process is more complicated than the painting process. Therefore, under the same conditions, the price of anodized aluminum plates is higher than that of painted aluminum plates, but painted aluminum plates are more cost-effective. The specific choice should be determined according to the use environment.

In general, aluminum plate products using the two aluminum plate surface treatment methods of baking paint and anodizing have their own characteristics and differences. Customers still have to choose the right product according to their own needs. FLAIT ALUMINUM supplies anodized aluminum products of various models and tempers from 1 to 8 series, and can also customize the production of painted aluminum products with different fabrics. If you have any needs, please contact our team.

Original Source:https://www.flait-aluminum.com/Anodized-Aluminum-Sheet-Coil.html

Tags:anodized aluminum sheet, painted aluminum sheet