- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

From the perspective of environmental and social benefits, global warming has become the focus of everyone’s attention, and the main reason for this is the relatively high emission of greenhouse gas CO2. According to the research report of the European Aluminum Association, every car used 1KG of aluminum alloy can reduce CO2 emission by 28KG. That is to say, if the aluminum alloy tank body is used to reduce the weight by 5 tons, the total CO2 emission can be reduced by 140 tons, the environment will be greatly improved, and the social benefits will be obvious. Therefore, aluminum alloy has incomparable advantages in terms of economic benefits, safety, environment and social benefits.

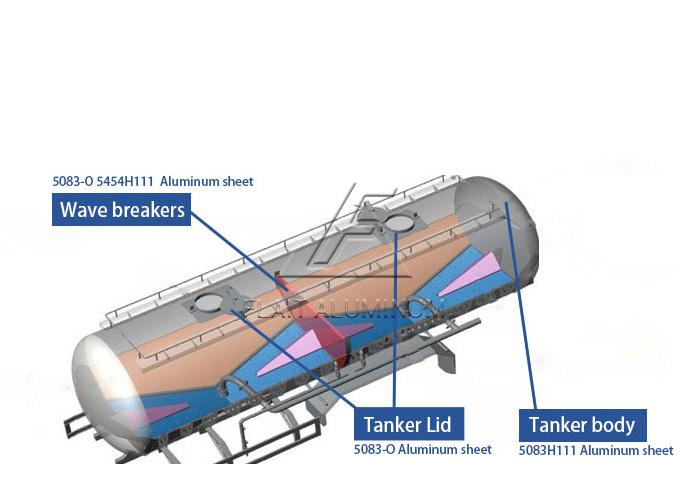

Tank trucks are tank-shaped transport vehicles used to transport various liquids, liquefied gases, and powdered goods. At present, the materials used for oil tankers are mainly carbon steel and aluminum alloy. A complete tanker body generally requires 4-6 pieces of aluminum plates to be welded together. The most important tank body is made of 5083-H111 aluminum plates. The can lid is made of 5083-O aluminum plate, which is softer, but the can lid needs to be bent, and the partition part is also made of 5083-O. In addition, some manufacturers also use 5454-H111 aluminum plates to produce tanks.Click to Order

5083 oil tanker aluminum plate: it has high hardness, strong corrosion resistance and good weldability.

5182 tank truck aluminum plate: mainly used for low-load parts that require high plasticity and good weldability, and work in liquid or gaseous media, such as fuel tanks, gasoline or lubricating oil conduits, liquid containers and other small loads made by deep drawing parts: wire used to make rivets. The thin plate can be used to process can lids, automobile body panels, control panels, reinforcements, brackets and other parts.

Light weight

Light weightThe weight reduction of the body can improve the performance of the tank truck. The specific gravity of aluminum is about 1/3 of that of steel. The aluminum alloy material has the characteristics of light weight, which can effectively reduce the weight of the vehicle body. The light weight can also increase the payload of the tanker, so that the transportation volume increases, and finally more profits. At the same time, it can also reduce the fuel consumption of vehicles during transportation. According to research, 60% of the fuel consumption of tank trucks comes from the self-weight of the vehicle. Every 1 ton of the vehicle can save 0.6 liters of fuel consumption per 10 kilometers, so that it can be used for a long time. In the process, it can save a lot of fuel consumption and reduce the wear and tear on the tires. The light weight of aluminum alloy tank trucks means that the fuel consumption and pollution discharge of the car are reduced, and it also means that it is environmentally friendly, because the exhaust emissions contain a lot of carbon dioxide, which is a major source of pollution to the environment. Therefore, the application of aluminum alloy materials is a great contribution to environmental protection. made a contribution.

Long service life and strong corrosion resistance

Long service life and strong corrosion resistanceCompared with ordinary carbon steel tank cars, aluminum alloy tank cars have stable chemical properties and are not easy to corrode. Generally, the service life of aluminum alloy tank cars is about 15-20 years, while the service life of carbon steel tank cars is only 7-9 years. Due to the good corrosion resistance of aluminum alloy, the aluminum alloy tank body can keep bright and beautiful, and the surface is more beautiful; and it does not need any spraying or surface treatment, and it is very easy to clean, so the maintenance cost of aluminum alloy tank trucks is quite small.

Beautiful appearance and superior performance

Beautiful appearance and superior performanceThe aluminum alloy has a beautiful appearance and good ductility. The use of separate warehouse technology can be compatible with the storage and transportation of various materials. The adoption of a closed filling system is more than twice as efficient as traditional loading and unloading.

High security

High securitySafety is very important for oil tank trucks. The aluminum alloy tank truck has a lighter body and a lower center of gravity, which makes it safer to drive. Aluminum alloy is a non-combustible material, and it is not easy to generate sparks, and there is less static electricity accumulation. This greatly reduces the probability of accidents. The aluminum alloy is easy to deform, so that it can absorb the energy generated by the collision in the event of a collision, and the tank body is not easy to crack. When the tank truck collides, due to the good electrical conductivity of the aluminum alloy, little static electricity accumulates on the tank body, so no sparks will be generated, and accidents such as explosions will not occur. At the same time, the aluminum alloy can well absorb the instantaneous energy generated when the tank body collides or rolls over, and will not cause cracking of the tank body, leakage of oil and other items, and will not directly cause explosion and environmental pollution. In addition, since the weight of the tank body is greatly reduced, the center of gravity of the tanker is correspondingly lowered, thereby reducing the possibility of the tanker rolling over and improving its driving performance.

No special processing technology

No special processing technologyAs the third most abundant element in the earth’s crust, aluminum is very abundant (8.23%). Aluminum alloy is also the second most widely used metal after steel, and its processing technology is very mature. Welding methods such as MIG, TIG, resistance welding, and FSW can be used to weld aluminum alloys. At the same time, aluminum alloys can also be bent, stamped and deep drawn to process tank cars.

High recycling value

High recycling valueDue to the high corrosion resistance of aluminum alloy, the price of aluminum is relatively high, so when the aluminum alloy tank is scrapped, its recycling price is also relatively high. Under normal circumstances, the recovery value of the tank body is more than 85% of the original aluminum.

Original Source: Aluminum Sheet for Tank Truck / Fuel Tanker

Tag: 5083 aluminum plate , 5454 aluminum plate,5182 aluminum plate