- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

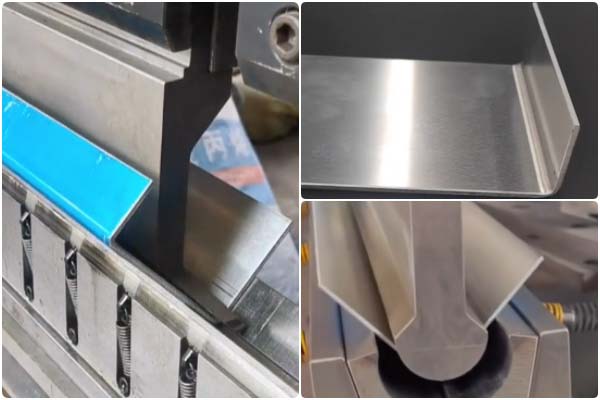

In the daily processing and use process, it is found that aluminum plates are easy to break after bending. What is the reason for this phenomenon? How to avoid it?

1. Hardness of aluminum plate

1. Hardness of aluminum plateAluminum plates with too high hardness are prone to breakage when bending. Therefore, when selecting aluminum plates, you should choose aluminum plates with moderate hardness and high quality. Generally speaking, series 1, 3, and 5 are more commonly used. These three series of aluminum plates are moderately soft and hard, suitable for bending processing, while series 6 and 7 have too high hardness and need to be annealed before bending processing. You should pay special attention to this when purchasing.

2. Thickness of aluminum plate

2. Thickness of aluminum plateIt is also difficult to process the bending process if the aluminum plate is too thick. Therefore, when selecting aluminum plates, you should not only look at the hardness, but also pay attention to the thickness of the aluminum plate, and try to use some thinner aluminum plates.

3. The size of the bending R angle

3. The size of the bending R angleThe larger the bending R angle, the greater the success rate of the bending processing, so try to increase the bending R angle.

4. The grain direction of the aluminum plate

4. The grain direction of the aluminum plateThe bending process has many requirements. In addition to the hardness and thickness of the aluminum plate, the bending must be perpendicular to the grain direction, and remember not to be parallel. For aluminum plates that need to be stretched, the best order of the process is to bend first and then stretch, which will greatly reduce the bending and cracking of the aluminum plate.

When performing the bending process, there are also requirements for the tempers of the aluminum plate. The best bending state should be a semi-hard state, which is often called the H24 temper. The softest state, the 0 temper, is too soft and is not suitable for bending processing.

Tags:aluminum plate