- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

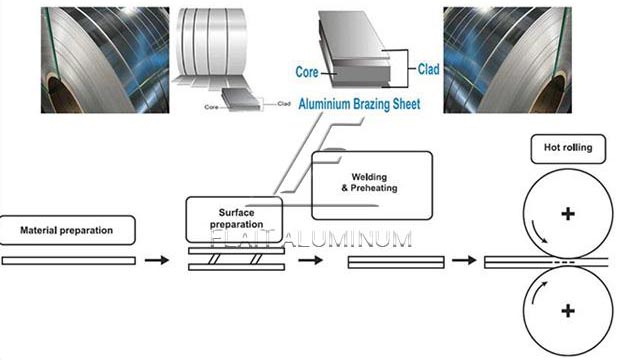

Brazing aluminum sheet coil strip refers to a process of joining two or more aluminum sheets, coils, or strips together using a filler material known as brazing alloy. Brazing is a high-temperature process that allows the aluminum pieces to be bonded without melting the base metal. The filler material, typically in the form of a thin layer or pre-placed wire, is melted and distributed between the aluminum surfaces by capillary action, forming a strong metallurgical bond upon cooling.

3xxx series aluminum alloys: such as 3003, 3003MOD, 3103, etc. These aluminum alloys have good processability and weldability, and are often used as base materials for brazing clad plates.

4xxx series aluminum alloys: such as 4045, 4343, 4104, etc. These aluminum alloys are often used as brazing filler metal layers for joining other aluminum alloy layers.

7xxx series aluminum alloy: 7072 aluminum alloy has high strength and excellent corrosion resistance, and is suitable for some brazing clad plates with high performance requirements.

It can join different types of aluminum alloys, avoiding cumbersome surface treatment procedures, and can produce firm and void-free joints to ensure airtight connections.

It can join different types of aluminum alloys, avoiding cumbersome surface treatment procedures, and can produce firm and void-free joints to ensure airtight connections. There are no air holes, cracks, etc. when the brazed aluminum plate is welded. The surface of the weld is bright and the weld is uniform.

There are no air holes, cracks, etc. when the brazed aluminum plate is welded. The surface of the weld is bright and the weld is uniform. The brazing process can achieve excellent thermal conductivity between aluminum parts, making it suitable for heat exchangers and other cooling components.

The brazing process can achieve excellent thermal conductivity between aluminum parts, making it suitable for heat exchangers and other cooling components. Brazing aluminum coils and strips can also connect thin aluminum materials.

Brazing aluminum coils and strips can also connect thin aluminum materials.Brazing aluminum sheet coil strip is commonly used in various industries for manufacturing heat exchangers, evaporators, condensers, radiators, and other components requiring a strong, leak-tight, and thermally conductive joint. It is particularly prevalent in the automotive, aerospace, HVAC (heating, ventilation, and air conditioning), and refrigeration industries.

Original Source: https://www.flait-aluminum.com/Brazing-aluminum-sheet-coil-strip.html