- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

◆ Lightweight

◆ Recyclable

◆ Excellent barrier properties

◆ Good formability

◆ Bright decorative effect

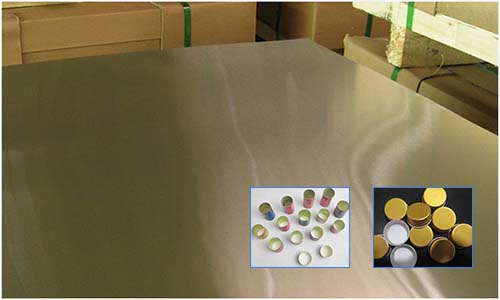

Aluminum anti-theft bottle caps are made of high-quality special aluminum alloy materials and are mainly used for packaging of wine, beverages (steamed or non-steamed), medical and health products, cosmetics and other products, and can meet special requirements such as high-temperature steaming and sterilization. Its characteristics are simple appearance, fine production, and advanced printing technology to make it consistent in color and exquisite in pattern. Compared with plastic bottle caps, it not only has good performance, but also low cost, no pollution, and can be recycled.

Aluminum bottle caps generally use 1060 aluminum coils, 8011 aluminum foils, 3105 aluminum plates, 3104 aluminum plates, etc. The main states are H14, H16, H18, etc. The commonly used bottle cap material has a thickness range of 0.15mm-0.5mm, a width of 200-1500mm, a thickness tolerance of ±0.005mm, and a width range tolerance of ±1mm.

Aluminum bottle caps are generally processed on production lines with a high degree of automation, so the strength, elongation and dimensional deviation of the material are very strict, otherwise they will break or crease during deep drawing. In order to ensure that the bottle cap is easy to print after forming, the bottle cap material plate surface is required to be flat, without rolling marks, scratches and stains.

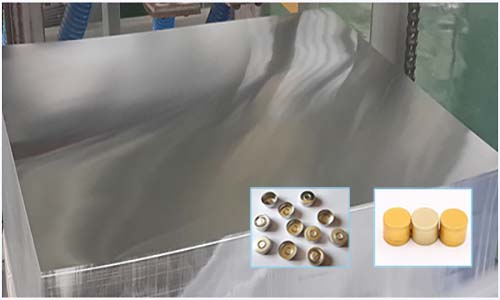

◎3105 bottle cap aluminum sheet and 3104 bottle cap aluminum sheet belong to 3 series aluminum-manganese alloys, with good rust resistance and good deep drawing effect.

◎3105 aluminum plate is very suitable for making wine bottles, beverage bottles, soda water, juice, energy drinks and high-end cosmetics bottle caps.

◎3105 aluminum plate is used for beer and red wine screw caps, with a main thickness of 0.15-0.3mm, and the states are H14, H16, H24, etc.

◎8011 aluminum foil is the main material for PP/ROPP bottle caps. It has good deep-drawing performance, low ear-making rate, and has a certain strength after hardening, which is more in line with the requirements of bottle caps.

◎8011 H16 aluminum foil is used for medical bottle caps. The aluminum caps are thin and easy to open. They are often used to seal bottled liquids such as oral liquids, antibiotics, and infusions.

◎1060 aluminum sheet has good yield strength, high elongation, good conductivity, high formability, and competitive price.

◎1060 aluminum sheet is combined with plastic to make bottle caps. Since the aluminum-plastic combination part will contact the liquid in the bottle, most of them are used in the cosmetics industry, and some are also used in the pharmaceutical industry.

◎1060 H24 aluminum sheet is widely used in the packaging of alcoholic beverages, beverages (with or without gas) and medical and health products, and can meet the special requirements of high-temperature cooking and sterilization.

1. Product specifications

1. Product specificationsBottle cap aluminum materials use different alloys and have different prices. 8011 aluminum foil is more expensive than 3104 aluminum plate; bottle cap aluminum materials have different specifications, and the length, width, thickness, and size of aluminum alloys are different. Different states have a certain impact on the price. Generally speaking, the thinner the bottle cap aluminum plate, the more expensive it is.

2. Raw material prices

2. Raw material pricesAny item has a raw material cost. The raw material of aluminum alloy is aluminum ingot. The quality of products made by purchasing high-quality aluminum ingots will be more guaranteed. If the raw material cost is high, the price of aluminum plate for bottle caps will inevitably be more expensive; on the contrary, if aluminum ingots containing a certain amount of scrap aluminum are used, the quality will also be affected, and the price will be lower.

3. Manufacturers

3. ManufacturersGenerally, manufacturers are divided into direct sellers, agents, and middlemen. If it is a direct selling manufacturer, there are not too many intermediate links, and its sales price is low; if it is an agent and distributor, the sales price must be high.

Flait Aluminum is a manufacturer integrating R&D, design and sales. Under the premise of ensuring product quality, adopts the sales policy of small profits but quick turnover, the company strictly controls the profit margin, the price of aluminum sheet and aluminum foil for bottle cap materials has great competitive advantages. Contact us to get expert advice and support for your needs. Click to Order

Original Source:https://www.flait-aluminum.com/Aluminum-Sheet-Coil-for-Cap-Closure.html

Tags:3105 aluminum sheet,8011 aluminum foil,1060 aluminum sheet,3104 aluminum plate